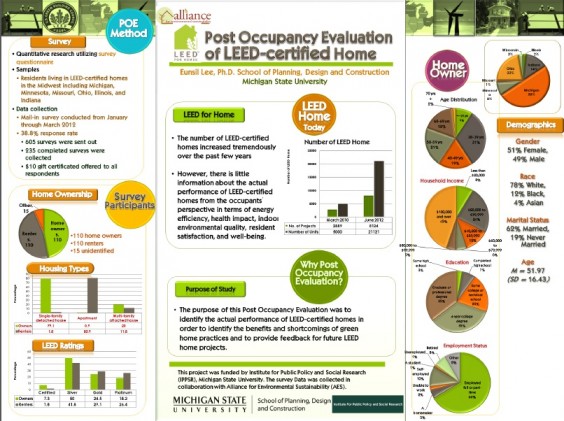

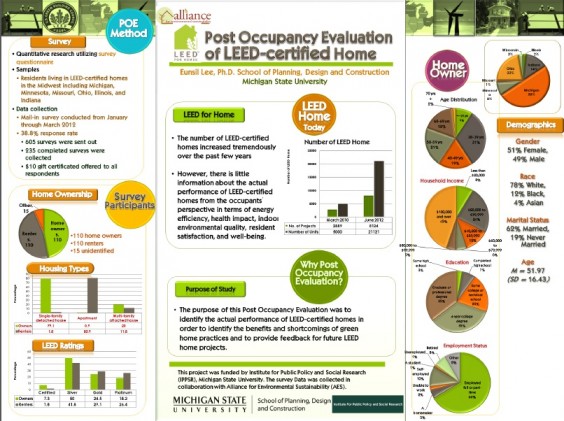

recently partnered with Michigan State University (MSU) to perform a Post-Occupancy Evaluation (POE) of 235 LEED-certified homes in the Midwest, and we are pleased to share the results. The goal is to identify the homes’ actual performance after people moved in, and also the

benefits and shortcomings of the current LEED for Home certification system. The survey consisted of various categories including (1) general satisfaction with the LEED-certified home, (2) satisfaction about the home in general and various aspects of the indoor environment, (3) overall well-being including the health impact, (4) energy efficiency and building performance, (5) the environmental behavior of residents, and (6) demographics.

The findings of this study revealed that most residents of the LEED-certified home were satisfied with their home and their quality of life in their home.

Continuing Education

- 1 GBCI – General

- 1 MI Contractor (Code & Green)

- 1 MI Architect

- If you need continuing education units for a license in another state, this course may apply. Please consult your state’s requirements.

This webinar is free to review. If you are interested in continuing education credits, you must follow the following steps:

1. Watch the webinar presentation by Eunsil Lee, PhD for FREE.

2. Contact to take the quiz and score at least 80% to be approved. Please also post a comment below and help add to the conversation.

3. Pay the fee below to get your certificate and CEUs. You must be an member to pay the reduced member fee.

Two methodological approaches were used for this study. Qualitative case studies were conducted with 15 LEED-certified Habitat for Humanity residents in Kent County, Michigan through in-depth interviews, observations, and IEQ measurement. 16 % respondents came from LEED-certified Habitat for Humanity homes in Michigan. These residents in particular, were more satisfied with their homes and their quality of life than residents of Non- Habitat homes were, although their satisfaction with their neighborhood and specific aspects of home environment (e.g., space layout, size of space, finishes, visual privacy, view, temperature, humidity) was lower than that of Non-Habitat residents. Residents of the Habitat for Humanity tended to perceive the improvement of their quality of life since moving into their LEED-certified home more strongly than residents of the Non-Habitat home did. They were also more satisfied with energy efficiency of their home than residents of the Non-Habitat home.

2 page graphic summary of Study PDF Here

Full 96 Page Report on Post Occupancy Study

Report Recommendations:

Promote sustainability in low-income housing: More programs should be developed that can offer incentives for participation in LEED green building certification programs and increase funding opportunities to cover the initial costs of sustainable home building for low-income families at both state and local levels, because those efforts will produce long-term economic and environmental benefits.

Improve the design of low-income green housing: Architects, designers, engineers, contractors, and facility managers can gain greater understanding of design and the performance of low-income green homes with the findings of this POE project by receiving feedback for the future projects. Although the houses were LEED-certified, some problems in maintaining the green features, building performance, and comfortable home environment were identified. Architects, designers, engineers, green policy makers, and Habitat for Humanity Affiliates should pay attention to the specific needs relevant to these issues to improve the design quality of low-income green home through the process of planning, design, and construction.

Implement Post-Occupancy Evaluation (POE): More extensive implementation of POEs is critical. Since LEED certification is based on “as-designed” performance, further implementation of POEs is exceptionally important to verify actual performance and expected performance. In particular, since there is no mandatory post-occupancy evaluation process included in LEED or other green home certifications, there is no empirical data to verify whether these green homes perform satisfactorily in terms of heating, cooling, or indoor environmental quality.

Contribute to the general body of knowledge: Although there is a consensus about the benefits of green homes, few empirical studies about the actual effects of LEED-certified green homes on residents’ health, comfort, and satisfaction have been conducted. The findings from this study therefore increased understanding of the benefits to be gained from LEED-certified low-income homes by applying empirically tested, research -based knowledge.

Promote public awareness: This report will educate the public about the impact of LEED-certified homes on (1) improving the residential environmental quality and energy efficiency, (2) reducing residents’ health risks and (3) enhancing residents’ comfort and satisfaction by disseminating the results of this research at conferences and by publishing articles in scholarly and extension journals.

Make a Policy Recommendation:

1) Incentives for green homes, such as LEED-certified homes, Energy Star Homes, or National Association of Home Builders’ Green certified homes, should be offered to developers, contractors, and homeowners. This will be critical for both new and existing homes located in the cold regions such as Michigan to encourage energy-efficient green home constructions for low-income families in order to offer lower utility bills.

2) Policy makers should collaborate closely with local builders and developers to apply more green home features to new or existing low-income houses. Certain types of incentives for local builders and developers are desired.

3) Post-occupancy evaluations of green certified homes should be encouraged, particularly for low-income housing. Continuous efforts should be made to save energy and keep green homes energy-efficient for these households and homeowners.

4) We suggest conducting POEs of green certified homes in five or ten years to preserve their green features and energy efficiency. Based on the POEs, the homes may or may not be repaired to keep the original functions of green features. In the POEs and repairing process, local home remodeling companies can be involved. Some incentives should be considered for the local companies or businesses to be involved in this green process if they are small or micro businesses. Tax reductions for these types of companies (i.e., energy auditors, window replacement companies) can promote small entrepreneurs working on sustainable housing projects in local communities. This can create more local jobs.

5) We suggest offering regular educational seminars for residents of green certified homes in order to offer precise information about the green features of their homes and educate them how to keep their homes green. On-site seminars can be offered one or two times in the development phase and right before the new owners take occupancy. Once residents move to their new homes, it is recommended to send flyers via mail or email to remind them of the green features of their homes and inform them of how to use and maintain these features. Mailed or emailed flyers will work better than on-site seminars because many residents have full- or part-time jobs.

6) In addition, incentives should be considered for upgrading low-income housing to make it more energy-efficient and environmentally friendly. Currently there is a 500 dollar maximum tax credit for upgrading any housing features to make them energy-efficient. This maximum should be increased to keep up with the real cost of upgrading energy-consuming HVAC systems to energy-efficient ones. In particular, more aggressive incentives should be offered to households below a certain income level so that homeowners can be more active in upgrading their conventional houses to energy-efficient green ones.

Thanks to the Michigan Applied Public Policy Research (MAPPR) Grant from the Institute for Public Policy and Social Research (IPPSR) and Michigan State University (MSU) who worked with to perform this Post-Occupancy Evaluation (POE).

See more details on a similar LEED Pre-Occupancy Report.

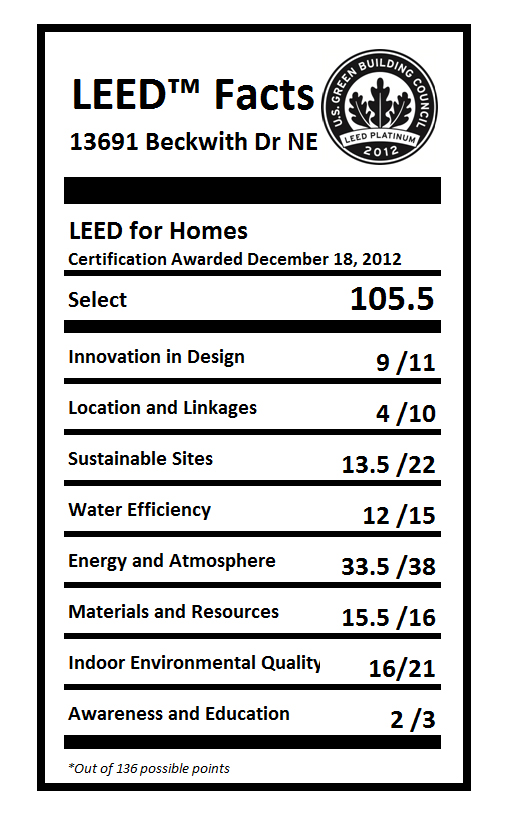

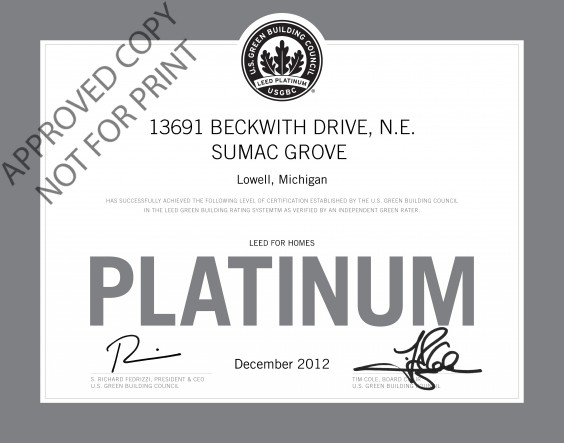

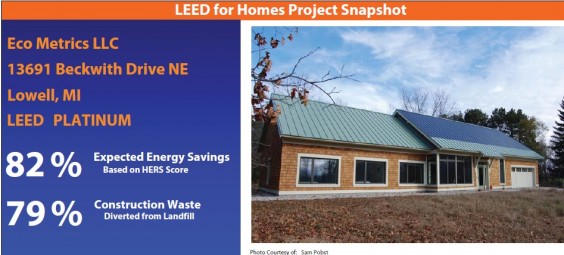

a MERV 10 rated filters and efficiently at 86 CFM, which fully circulates the air in the home approximately every 4 hours. The furnace itself runs on a single speed PSC motor which runs at set intervals and uses the ERV to moderate the temperature. The house also features a Superior Wall Foundation which contributes an R-Value of 5 to NuWool insulation installed on the walls for a total R-Value of 26. To further increase the insulation of the house the rim joists were also insulated and earn an efficient .3 U-factor windows were installed to reduce air leakage.

a MERV 10 rated filters and efficiently at 86 CFM, which fully circulates the air in the home approximately every 4 hours. The furnace itself runs on a single speed PSC motor which runs at set intervals and uses the ERV to moderate the temperature. The house also features a Superior Wall Foundation which contributes an R-Value of 5 to NuWool insulation installed on the walls for a total R-Value of 26. To further increase the insulation of the house the rim joists were also insulated and earn an efficient .3 U-factor windows were installed to reduce air leakage.

Recorded 1 Hour Webinar on the entire project – 1 AIA/GBCI

Recorded 1 Hour Webinar on the entire project – 1 AIA/GBCI

When Brian and Jeremy vanEyk (Vice President) were asked about their commitment to building LEED, they responded that Cottage Home is committed to utilizing healthy, affordable, efficient, and durable construction practices that are already above code, energy star and even LEED at times. Brian says he considers LEED only one of the many tools in his toolbox. Other such tools include creative design, customer service, careful selection of materials, and creating a sense of place. In order to make it simple for the customer, Cottage Home uses a fixed price prior to starting construction which already includes LEED qualifications. This allows some of the cost of LEED certification to be absorbed by both the customer and through the Cottage Homes marketing budget. Brian believes this method works due to his design and construction teams working together throughout the construction process, which creates a feedback loop that fosters constant improvement. Including LEED certification into the final cost helps facilitate more sales than presenting each option with separate pricing.

When Brian and Jeremy vanEyk (Vice President) were asked about their commitment to building LEED, they responded that Cottage Home is committed to utilizing healthy, affordable, efficient, and durable construction practices that are already above code, energy star and even LEED at times. Brian says he considers LEED only one of the many tools in his toolbox. Other such tools include creative design, customer service, careful selection of materials, and creating a sense of place. In order to make it simple for the customer, Cottage Home uses a fixed price prior to starting construction which already includes LEED qualifications. This allows some of the cost of LEED certification to be absorbed by both the customer and through the Cottage Homes marketing budget. Brian believes this method works due to his design and construction teams working together throughout the construction process, which creates a feedback loop that fosters constant improvement. Including LEED certification into the final cost helps facilitate more sales than presenting each option with separate pricing. Since many homeowners today are educated and concerned about sustainability and environmental issues, many take time to study the details of LEED on the website of Cottage Home and take comfort in knowing LEED is a third party certification. Clients are aware of LEED’s achievements and credibility, and often wonder about how changes to the house affect the LEED certification level. Much of Cottage Home’s customer base is from the Chicago area where LEED is prevalent in their office buildings, and a result, many clients have experienced the advantages offered by LEED construction firsthand. These clients have often already invested in commercial LEED projects and are now ready to transition these same high standards to their personal lives. Jeremy decided to experience the benefits of LEED firsthand and chose to have his

Since many homeowners today are educated and concerned about sustainability and environmental issues, many take time to study the details of LEED on the website of Cottage Home and take comfort in knowing LEED is a third party certification. Clients are aware of LEED’s achievements and credibility, and often wonder about how changes to the house affect the LEED certification level. Much of Cottage Home’s customer base is from the Chicago area where LEED is prevalent in their office buildings, and a result, many clients have experienced the advantages offered by LEED construction firsthand. These clients have often already invested in commercial LEED projects and are now ready to transition these same high standards to their personal lives. Jeremy decided to experience the benefits of LEED firsthand and chose to have his Building on the lake front comes with complications such as extreme wind loads, humid changes, temperature fluctuation, and other variables. To overcome these challenges, Cottage Home uses high performance home measures to control the entire process though design, build, and some maintenance which allows more control of green features. Cottage Home designs and builds what is right for each particular home which may result in homes varying in different HVAC, insulation, passive solar heating, and various climate control systems. One particular feature that is commonly used in these homes, including Jeremys, is an ERV (Energy Recovery Ventilator). An ERV automatically exhausts stale air from the inside of the house and replaces it with fresh air from the outside. Another key feature used in many of the homes is a geothermal system. There are a few different types used, but all contribute to the energy efficiency of the homes in some way. Several techniques are used to increase water efficiency in the homes, such as tankless water heaters, which only heat water when necessary, water collection systems to help with sprinking and irrigation, and faucets and showerheads that work with less water than traditional ones. Insulation, as well as materials such as flooring, home furnishings and walls are all aspects that need to be carefully considered when building these homes.

Building on the lake front comes with complications such as extreme wind loads, humid changes, temperature fluctuation, and other variables. To overcome these challenges, Cottage Home uses high performance home measures to control the entire process though design, build, and some maintenance which allows more control of green features. Cottage Home designs and builds what is right for each particular home which may result in homes varying in different HVAC, insulation, passive solar heating, and various climate control systems. One particular feature that is commonly used in these homes, including Jeremys, is an ERV (Energy Recovery Ventilator). An ERV automatically exhausts stale air from the inside of the house and replaces it with fresh air from the outside. Another key feature used in many of the homes is a geothermal system. There are a few different types used, but all contribute to the energy efficiency of the homes in some way. Several techniques are used to increase water efficiency in the homes, such as tankless water heaters, which only heat water when necessary, water collection systems to help with sprinking and irrigation, and faucets and showerheads that work with less water than traditional ones. Insulation, as well as materials such as flooring, home furnishings and walls are all aspects that need to be carefully considered when building these homes. As leaders in the industry we asked Brian and Jeremy what they saw in the future of design and construction. Jeremy believes that being able to evaluate the effectiveness of high performance systems and insulation through energy bills is important. Along with water collection systems to reduce storm water runoff and help irrigate the lawn. Brian agrees that we should have a system to allow clients to ensure they are getting the most effective homes. He foresees homes that can be manipulated to meet the client’s needs at any given time. An example of this would be homes with the ability to accommodate a family of four, which can then transition to accommodate sleeping arrangements for twenty. Along with being able to better meet a client’s needs, he would like to see energy loads distributed to only sections of the house in use, as well as the ability for clients to control how energy is used throughout the home (on site and from satellite locations). Cottage Home sees one challenge to moving forward with these ideas is getting sub-contractors to approach basic air sealing, insulation, proper HVAC sizing, and design aesthetics with an effective mindset. Cottage Home has established themselves as innovators and leaders in the design of luxury LEED lake front homes. They continue to partner quality, design and the environment hand in hand to produce sustainability along our beaches.

As leaders in the industry we asked Brian and Jeremy what they saw in the future of design and construction. Jeremy believes that being able to evaluate the effectiveness of high performance systems and insulation through energy bills is important. Along with water collection systems to reduce storm water runoff and help irrigate the lawn. Brian agrees that we should have a system to allow clients to ensure they are getting the most effective homes. He foresees homes that can be manipulated to meet the client’s needs at any given time. An example of this would be homes with the ability to accommodate a family of four, which can then transition to accommodate sleeping arrangements for twenty. Along with being able to better meet a client’s needs, he would like to see energy loads distributed to only sections of the house in use, as well as the ability for clients to control how energy is used throughout the home (on site and from satellite locations). Cottage Home sees one challenge to moving forward with these ideas is getting sub-contractors to approach basic air sealing, insulation, proper HVAC sizing, and design aesthetics with an effective mindset. Cottage Home has established themselves as innovators and leaders in the design of luxury LEED lake front homes. They continue to partner quality, design and the environment hand in hand to produce sustainability along our beaches.