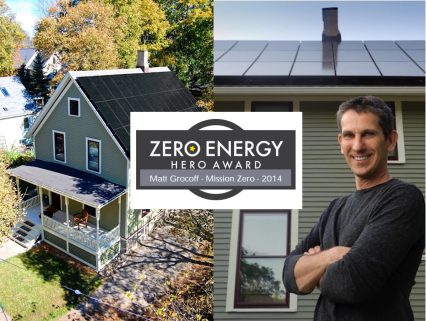

Mission Zero Home: A Greenstar Gold Remodel & CE Webinar

/0 Comments/in GreenStar, GS Gold, Michigan, Net Zero, Remodel, Single-Family Projects, Zero Hero Award/by Brett LittleWhile sitting in his living room, spending the day documenting his home to verify all the measures and requirements for GreenStar, I showed Matt Grocoff the GreenStar checklist tool and manual to give him an idea of what was needed for his project. After looking through it, his immediate response was, “I  wish I would have known about this when I started.”

wish I would have known about this when I started.”

Back in 2010, Matt began a journey. He purchased a 110 year old home in Ann Arbor, MI that has led him on the international road promoting net-positive homes and buildings. When he bought the home, he reviewed the LEED for Homes program but decided against it. He found it to be too invasive for what he wanted and could afford to do to his existing home. Matt, in partnership with Meadowlark, was a pioneer in the world of Green Home deep energy retrofits in the Midwest and has helped influence what can and should be done to bring an existing home to net zero energy.

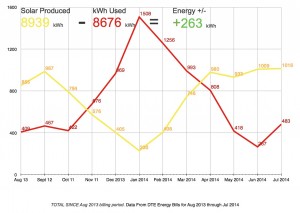

Despite lacking a good tool (like LEED or GreenStar), Matt and his family persisted on with the renovation. First they underwent a home energy assessment utilizing the HERS index. The results were off the charts – far above 100. “From there we needed to work backwards. Using the PV watts calculator, we determined we could get roughly 9,000 kwh of solar given size of our roof and available technology. For 9,000 kwh to be sufficient, we realized we needed to improve the home’s HVAC, insulation, air sealing, appliances, lighting and other areas to get us down to that level without sacrificing comfort or a normal lifestyle,” Matt explained. Through the detailed but simple measures listed below, Matt’s home is a proven Net Zero home – even while driving a Chevy Volt and charging it at home! They plan to add a little more PV so that they can update their vehicle to a Tesla and still remain net zero.

One thing that I learned while sitting down with Matt and discussing the push back to an all-electric home is the claim that it’s a waste because of electric line loss of up to 10% energy. Most utilities and even the HERS score incentivize the use of Natural Gas. Matt enlightened me to a partnership between Google and the Natural Resource Defense Council that is utilizing Google vehicles to show major natural gas leaks in gas lines all over the country. These leaks are not accounted for in line loss of energy, while electric is.

One thing that I learned while sitting down with Matt and discussing the push back to an all-electric home is the claim that it’s a waste because of electric line loss of up to 10% energy. Most utilities and even the HERS score incentivize the use of Natural Gas. Matt enlightened me to a partnership between Google and the Natural Resource Defense Council that is utilizing Google vehicles to show major natural gas leaks in gas lines all over the country. These leaks are not accounted for in line loss of energy, while electric is.

Beyond energy, Matt and his family were inspired by the Living Building Challenge (which they are pursuing) and are now, in partnership with U of M Blue Lab Engineering and a Ford Foundation Grant, exploring Net Zero water. The goal is to be able to design a system that captures 100% of rainwater off the roof, stores the water, and cleans it to potable and non-potable standards. The final step would be attaining approval by the municipality to install the system. One interesting challenge the Grocoffs must overcome is that their asphalt shingle roof has been proven to contaminate runoff water toxins such as lead. These toxins are very expensive to remove. However, the cost to seal the existing shingles or replace the shingles may prove cheaper in the long run than maintaining a clogged water filtration system. Another element that Matt and his family are working on is to prevent 100% of the home’s storm water from getting into the city sewer. This could be done partly by capturing water from the roof, partly by adding rain gardens. The most unique idea is a partnership with the city that would replace the sidewalks in front of the house with a system that will direct rainwater from the sidewalk to his rain gardens. If it works, replacing sidewalks this way could model in Ann Arbor and in other cities around the country how to reduce the expense and pollution caused by run off and storm water.

Why water?

Even though we live near the Great Lakes and have access to more water than we need, it’s no secret that quality and quantity of water is diminishing. “While all the news media was going on about California this year, much of Michigan was experiencing a major drought and lack of underwater aquifers. It’s important that we have deeper conversations about water in our state and how to protect it through simple things we can to do our buildings,” says Matt.

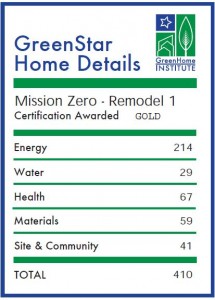

Because of Matt’s diligence during the renovation process, his home was easily back certified to GreenStar standards. He blew the gold standard “out of the water.” explained Brett Little. We also are grateful to work with him to develop recommendations for existing homeowners using the GreenStar tool to achieve our new zero energy certification. We are very excited to award Matt and the Mission Zero Home with the GreenStar Gold Type 1 Remodel Certification and to induct him before anyone else into our Zero Hero Hall of Fame. We will be monitoring Matt’s house and following his case study as he supplies us with Return on Investment, future energy use, water use, indoor air quality testing data, and other interesting aspects as he continues to do more to his home.

Free Webinar worth 1 hour of continuing education – GBCI, AIA (HSW), NARI Green & LFA and review utility data. More here.

Project Details

Location: Ann Arbor, MI

Bedrooms: 3

Bathrooms: 2

Living Space: 1300 sq. ft.

2,600 sq. ft. of conditioned space

General Contractor: Matt Grocoff, Thrive Net Zero Consulting

Whole-House Performance Contractor: Meadowlark Energy

Greenstar checklist submittal with full details on the home.

Website: Happy Home How! http://www.happyhome.how/

Energy

Attic Insulation/Air Sealing: R-30Demilec Sealection 500

Wall Insulation: R-13 Farmers dense-packed cellulose insulation

Rim Band Joist: Air sealed and insulated

Windows: Trapp low-e storms

Air Tightness: 4.75 ach50

Alternative Energy: SunPower 8.1 kW photovoltaic system

Heating/Cooling: 3-ton Water Furnace Envision

Window Restoration: Wood Window Repair Company

Lighting Controls: Watt stopper motion sensor light switches

Power Strips: Smart Strip Power Strips

Window Treatments: EcoSmart Insulated cellular shades

Water Heater: Geothermal + Air Heat pump

Dryer: Heat pump technology

Appliances: Induction Cooktop

HERS Index: 37

Residential Energy Performance Score: 61 (rated at 9,000 kwh/year)

Water Conservation

Toilets: Caroma Dual-Flush

Showerheads: Bricor 1 GPM (HET)

Faucets: Bricor .38 GPM!

Irrigation: Rain barrels (salvaged from St. Jullian’s Winery)

No Garbage Disposal

Health

Whole-House Ventilation: Ultimate Air ERV

Furnace Filter: MERV 8

Paints: Zero VOC – Benjamin Moore Aura, AFM Safecoat, Sherwin Williams Harmony

Floor Finish: Bioshield Hard oil #9

Molding Finish: Hock natural shellac

Bedding: NaturePedic mattress

Flooring: Mostly wood through out

Knob & Tube Wiring Removed

Materials

Salvaged Doors: Habitat for Humanity ReStore

Picture Frames: Urban Ashes

Salvaged Wood Stock: Urban Wood

Outbuilding: Chicken coop salvaged from neighbor’s playhouse

Carpet: Wool stair runners from G & K Flooring

Retained Existing home through minor remodel!

Perimeter plantings kept up to 24 inches away from the home.

Milwork, countertops, cabinets, trim, floors, and windows all refurbished and reused.

Site & Community

Conventional turf grass reduced

Home recycling and compost center

Walk Score – 70 +

Public transportation and biking is good

65% of undeveloped site is permeable

40% native / drought tolerant plantings

Rain gardens to stop storm water run off

*Some of this list was borrowed from Matt’s house being featured on Green Building Advisor.

Watch the on-demand webinar

Continuing Education – 1 CEU

- GBCI

- AIA (HSW)

- Living Future (LFA)

- NARI Green

- Local & State Architect & Contractor (MI approved)

1.Watch the recording here

3. Take quiz below

4. Pay fee

- Member Rate $9.99

- Non Member Rate $19.99

Webinar: Journey to Almost Passive House & LEED Platinum Near-Zero Home

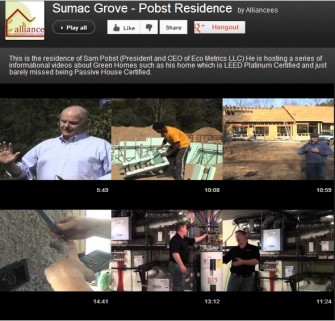

/0 Comments/in Local, Illinois, Indiana, LEED Platinum, Michigan, Minnesota, Net Zero, Ohio, Single-Family Projects, Wisconsin/by Brett LittleFinally it is here – after 2 years of filming and a big thanks to four Grand Valley State University Interns, 2 hours of video detailed in over 10 sections on the how and why of LEED for Homes and Passive House construction specifically to Sam Pobst’s home.

Sam and some of the other high performance building professionals take us through many aspects: site selection/design, insulation, heating and cooling, passive building, water efficiency and renewable energy.

What makes it Green? For starters, Michael Holcomb – President/CEO and owner of Home Inspector General has called this “the tightest home I have ever tested.” It comes in at 0.44 ACH @50PA (for all you energy geeks). Michael has test thousands of homes and buildings in the Midwest in his 20 years of experience, so that is saying something.

Next, this project almost achieved Passive House standards! Sam worked with an experienced PHIUS rater “John Semmelhack” to use the advanced modeling software to design his house. The house tested below the air change requirements of Passive House but only made 7.20 KBTu’s as opposed to the required 4.75 (energy geek talk). Sam’s reasoning: “The primary driver of that cost was the building geometry. Since a primary objective was to build a barrier free home, we designed it all to be on one level. This meant that the ratio of exterior wall and roof area to the floor area was not optimal for thermal design (of Passive House). It was more important to us to have the barrier free design than to meet the PH requirements, though we came very close. The only changes we made from the original PH design was to reduce the thickness of the perimeter walls from 22” to 19”, and specify a window that was not quite as high performing as the one that would attain the PH rating.” Sam told me that there was 99 year back on the window required to meet the standard (at that time).

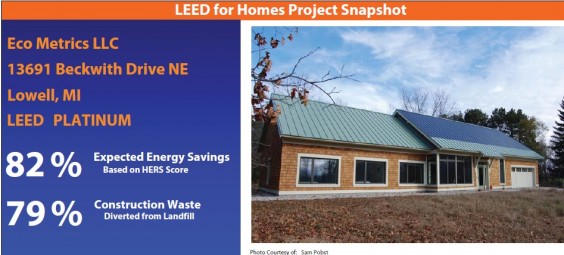

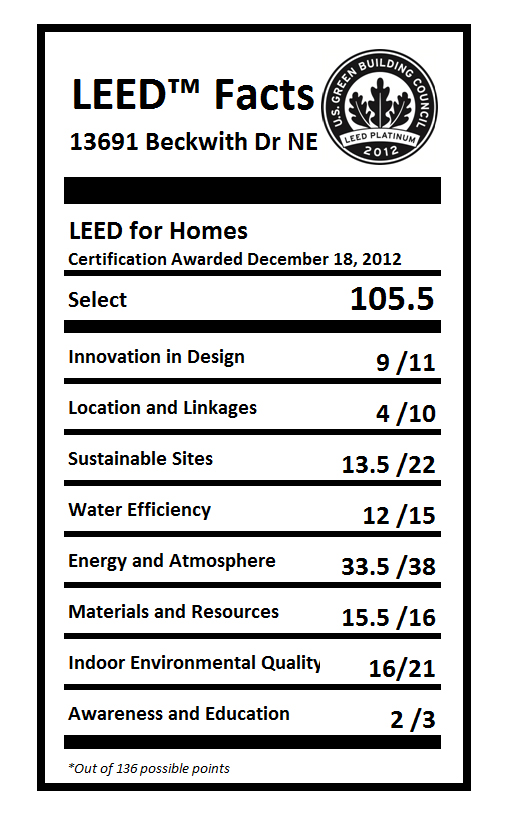

Last, LEED for Homes Platinum Certification has been achieved. This

Last, LEED for Homes Platinum Certification has been achieved. This

requires 3rd party onsite verification that proves through actual testing that the home is green.

This must have cost millions right?

“We spent $167.00/Square Foot, but if you add in O+P, design fees, and my sweat equity, I estimate about a $200/Square Foot cost to construct.” – Sam Pobst

• Gross Square Feet 2010

• Basement Square Feet 851

• Conditioned Square Feet 2547

• Garage / Workshop 621

• $167/Square Foot Hard Cost

• $200/ Square Foot Buildable Cost

- + Overhead and Profit

- + Design Fees

- + Sweat Equity

Objectives

- Gain a basic understanding of the Passive House (PH) design standards for homes and products or technologies are needed to achieve it.

- Discriminate between LEED, Net Zero, universal design and Passive House objectives and how they interact.

- Learn about behind the wall thermal envelope strategies for a super tight and insulated home.

- Identify costs, ROI and payback on high performance home LEED projects

Continuing Education

- 2 GBCI – LEED Specific

- 2 AIA – LU|HSW

- 2 MI Contractor (Code & Green)

- 2 MI Architect

- If you need continuing education units for a license in another state, this course may apply. Please consult your state’s requirements.

Project utility data update and ROI data

These webinars are free to review. If you are interested in continuing education credits, you must follow the following steps:

1. Read the info above, watch the webinars for FREE and check out the Project Profile.

2. Take the 13 question quiz and score at least 80% to be approved. Please also post a comment below and help add to the conversation.

3. Pay the fee below if this is not taken as part of our GreenHome Associates series to get your certificate and CEUs. You must be a member to pay the reduced member fee.

Further Resources

Read back on Sam’s progress documented on his Blog and stay informed as he monitors the home’s energy use, durability, comfort, indoor air quality and water use. http://sumacgrove.blogspot.com/2013/01/certified.html

Recorded 1 Hour Webinar on the entire project – 1 AIA/GBCI

Recorded 1 Hour Webinar on the entire project – 1 AIA/GBCI - 2 Hour GBCI approved Film Series documenting the project from start to post occupancy informed can be seen here for free

Greenest Home in West Michigan Certifies LEED Platinum

/0 Comments/in LEED Platinum, Michigan, Net Zero, Passive House, Single-Family Projects/by Brett Little1 Hour Recorded Webinar Available Now – 1 AIA/GBCI

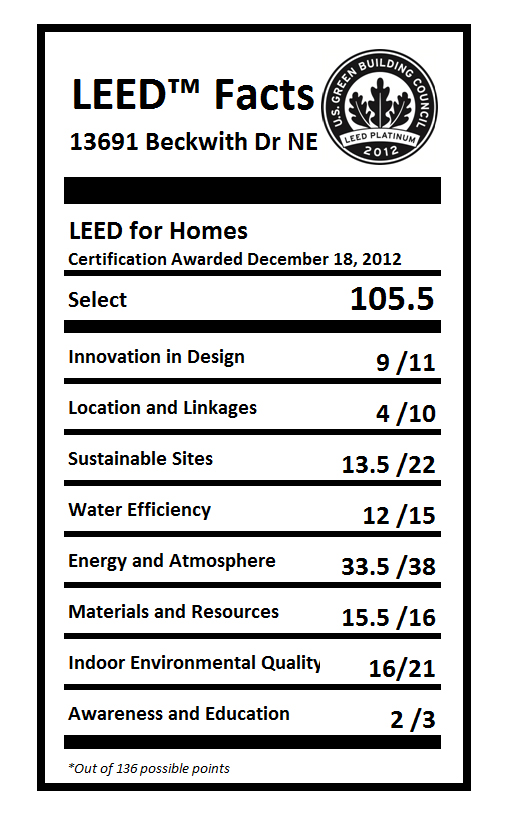

” In the 5 years I have been involved with and Regional Green Building Certified Homes, I think I can finally throw my 2 cents in the ring and call this the Greenest Home in West Michigan” – Brett Little, Executive Director

What make’s it the Greenest? For starters, Michael Holcomb – President/CEO and owner of Home Inspector General has called this “the tightest home I have ever tested.” It comes in at 0.44 ACH @50PA (for all you energy geeks). Michael has test 1,000’s of homes and buildings in the Midwest in his 20 years of experience so that is saying something.

Next, this project almost achieved passive house standards! Sam worked an experienced PHIUS rater “John Semmelhack” to use the advanced modeling software to design his house. The house tested below the air change requirements of Passive House but only made 7.20 KBTu’s as opposed to the required 4.75 ( Energy Geek Talk) Sam’s reasoning’s “The primary driver of that cost was the building geometry. Since a primary objective was to build a barrier free home, we designed it all to be on one level. This meant that the ratio of exterior wall and roof area to the floor area was not optimal for thermal design (of Passive House). It was more important to us to have the barrier free design that to meet the PH requirements, though we came very close. The only changes we made from the original PH design was to reduce the thickness of the perimeter walls from 22” to 19”, and specify a window that was not quite as high performing as the one that would attain the PH rating.” Sam told me that there was 99 year back on the window required to meet the standard (at that time).

3rd, First Zero Energy Home in West Michigan (if anyone wants to dispute that let us know!). Obviously we can’t officially call it Zero Energy without a year’s worth of data but we will keep you all up to date to see it makes it. The HERS score is not 0 but it is 18 which is the lowest in West Michigan with A home in Stanwood and hour north getting a 12. There is a lot of mis-information out there stating that a HERS of zero is required to be “Zero Energy” but in practice we see homes scoring HERS of 35 and achieving Zero Energy.

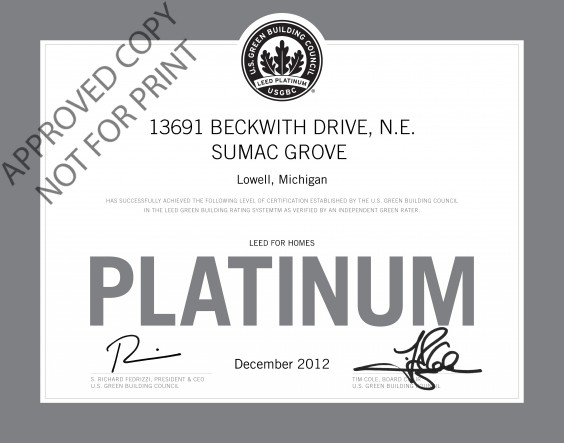

Last, LEED for Homes Platinum Certification has been achieved. This

Last, LEED for Homes Platinum Certification has been achieved. This

requires 3rd party onsite verification that proves you the home is green through actual testing.

But, but… This project is in Lowell outside of an Urban Area and lacks community resources and connectivity. It’s true, the one place that this house poorly scores is in location efficiency. You can find data to support that reliance on automobiles is more costly and has more CO2 emissions than very well insulated home. Currently Sam is using the home as his office as well as his living space and so he does not have to drive to an office in a far away location. He can grow alot of food on the site as well and eventually add more solar and purchase an electric car to power it with all Solar.

This must have cost millions right?

“We spent $167.00/Square Feet, but if you add in O+P, Design fees, and my sweat equity, I estimate about a $200/ SF cost to construct.”

• Gross SF 2010

• Basement SF 851

• Conditioned SF 2547

• Garage / Workshop 621

• $167/SF Hard cost

• $200/ SF Buildable cost

- + Overhead and Profit

- + Design fees

- + Sweat Equity

Further Resources

Read back on Sam’s progress documented on his Blog and stay informed as he monitors the home’s energy use, durability, comfort, indoor air quality and water use. http://sumacgrove.blogspot.com/2013/01/certified.html

Recorded 1 Hour Webinar on the entire project – 1 AIA/GBCI

Recorded 1 Hour Webinar on the entire project – 1 AIA/GBCI - Sign up for our mailing list to stay informed on Spring 2013 Tours. Potential GBCI Credit

- 2 Hour GBCI approved Film Series documenting the project from Start to post occupancy informed can be seen here for free

- Contact with Questions Sam Pobst, BO+M, BD+C, Homes and ID+C, a USGBC LEED Faculty™

Principal

ecometrics llc

P. 616.897.4967 C. 616.648.7493

Email sam@ecometrics.biz

Ann Arbor Rehab, Green Building, Green Business

/0 Comments/in Education and Events, Gut Rehab, LEED Platinum, Michigan, Net Zero, Single-Family Projects/by Brett LittleAnn Arbor Michigan, a hot bed for sustainable home development is at it again

with a LEED for Homes registered gut rehab that is on track to be Platinum Certified as well as net zero site energy. Dubbed the Rancho Deluxe project, this ambitious rehab will feature both the Atomic Zero Home and a new structure and the home offices of Urban Ashes, a small business owned and operated by Paul Hickman. This home will feature geothermal, occupancy sensors, 10 kws of PV, mostly locally sourced or re used products, storm water reduction, native meadow installed and more. The Urban Ashes Studio addition is  rumored to be one of Ann Arbor’s first straw bale wall assemblies once approved by the city and the studio it self is an authentic sustainable business with a triple bottom line. The company utilizes otherwise thrown out city trees to build furniture and picture frames while employing transitional/disabled labor. The company was recently featured in a local West Michigan news story based in a made in Michigan edition

rumored to be one of Ann Arbor’s first straw bale wall assemblies once approved by the city and the studio it self is an authentic sustainable business with a triple bottom line. The company utilizes otherwise thrown out city trees to build furniture and picture frames while employing transitional/disabled labor. The company was recently featured in a local West Michigan news story based in a made in Michigan edition

Despite Heat & Drought, Michigan LEED Platinum Home Stays Cool & Refreshed

/0 Comments/in LEED Platinum, Michigan, Net Zero, Single-Family Projects/by Brett Little“We installed our original cooling system in July 2010 and it has worked reasonably well, but over the last few weeks we’ve had a hot spell with daytime temperatures mostly in the upper 90’s and well over 100 degrees Fahrenheit for a few days. That’s normal in some parts of the world but in Michigan, we consider that HOT! Over two weeks of unusually hot weather the house reached 77 degrees at the warmest point when it was 105 outside, which is actually pretty good since we’re cooling the entire house for about 30 cents per day….The Systems total cooling capacity is very small however, so it is practical only because our total cooling load is very small due to the extreme level of insulation in the house, because our south-facing windows have carefully designed overhangs that block direct sun in mid summer, and because we use very efficient appliances that add very little additional heat to the house.

“Since we’ve had a hot, dry spell for the last 4 weeks we have been using a lot of cistern water for the gardens, and we’re down to about 36 inches or 4,300 gallons, out of a total capacity of 12,000 gallons. Hopefully we’ll get some significant rain soon to replenish our irrigation water supply, but we can refill it from the well if necessary.” – Jay & Liz McClellan.

Learn more at

http://www.brainright.com/OurHouse/Construction/CoolingSystem/enhanced.shtml

Wisconsin Passive House owner says drop on by anytime!

/0 Comments/in Local, Common Myths, LEED Platinum, Net Zero, Passive House, Single-Family Projects, Wisconsin, Zero Energy Capable/by Brett Little“I want as many people to come into this house as possible. Anyone who reads this can knock on my door and I’ll give them a tour. The whole point is to share and learn from each other, to take ideas from here and do them elsewhere.” – Sonya Newenhouse

With Carly Coulson as the certified Passive House designer. This tiny (968-square-foot) kit house has a treated floor area of  888 square feet (82.5 m²). This project sports local windows and Cardinal triple-pane glass, while the doors are Energate. The NewenHouse is wrapped in a jacket of cellulose – and similarly comes in well under the specific space heating demand.

888 square feet (82.5 m²). This project sports local windows and Cardinal triple-pane glass, while the doors are Energate. The NewenHouse is wrapped in a jacket of cellulose – and similarly comes in well under the specific space heating demand.

Carly recently presented the project at the Hannover Passivhaus conference. Here are some of the project specs:

- Space heating demand: 11.4 kWh/m²a (3.61 kBTU/ft²a)

- Primary energy demand: 104 kWh/m²a (32.9 kBTU/ft²a)

- Blower door: 0.51 ach50

- Wall U-factor: 0.09 W/m²K (R-63)

- Slab U-factor: 0.10 W/m²K (R-57)

- Roof U-factor: 0.06 W/m²K (R-94)

- (7,795 HDDs)

The project is also rocking a solar domestic hot water system (Velux) that is expected to provide nearly two-thirds of the domestic hot water needs, and a PV system for site net zero energy.

The project went through BRE in Watford, UK, for Passivhaus certification, is Energy Starcertified, and is expected to hit LEED for Homes Platinum after Landscape verification by the Green Rater Laura Paprocki.

Total cost for NewenHouse – including solar DHW, PV, and accessory structures – is a whopping $173/sf. If there was a LEED Titanium, this über-tiny Passivhaus in an “extreme” environment would surely qualify.

Newenhouse, who aptly describes herself as an eco-entrepreneur, is also founder and president of Community Car LLC in Madison, and just sold the Madison Environmental Group, a business she founded 13 years ago, to an employee. In the next year, she plans to launch a business selling three house designs — a 500-square-foot one-bedroom, an 800-square-foot two-bedroom, and a 1,000-square-foot three-bedroom. An option for a detached stuga, Swedish for “cabin,” includes storage space, a root cellar, sleeping loft, sitting area and wood stove. With her business, Newenhouse says she is trying to bring together three movements: the green building movement, the small house movement and the sustainable- or simple-living movement.

A brief overview of her kit house can be found at http://www.madisonenvironmental.com/documents/NewenHouseHandout_10%2010%2011%20(3).pdf

You can contact Newenhouse at 608-220-8029 or Sonya@madisonenvironmental.com. A link to her blog is on the a at madisonenvironmental.com. Or if you’re planning to drop in, which she says she welcomes, she lives at 422 Hickory St. in Viroqua WI.

Want to learn more about Passive House features & LEED? is hosting a free webinar of another Homeowner’s journey in Michigan who attempted passive house & is on track for LEED Platinum. Missed it? It will be recorded and a 2 hour video series on it’s construction & post occupancy living will be out by Fall. https://greenhomeinstitute.org/education-and-events/a-journey-to-passive-house-leed-homeowners-tale-free-webinar/

This article is a mash up between Joe Orso of the Lacrosse Tribune and Mike Eliason of Green Building Advisor. Their stories can be found here

Sheltered: Underground & Off the Grid.

/0 Comments/in Education and Events, Michigan, Net Zero/by Brett LittleAdam Bearup of Hybrid Homes, past board member and builder of many of West Michigan’s earlier LEED for Homes projects is presenting a unique northern Michigan project. He will also be debuting is brand new book. More details below or catch the trailer here http://www.youtube.com/watch?v=D7xoMIgEB-Y&feature=youtu.be

Homeowner of 1st LEED certified home in Ann Arbor tells his success story

/0 Comments/in LEED Platinum, Michigan, Net Zero, Single-Family Projects/by Brett Little** Update 9/15/2013 – This home is about to go back on the market – If you are interested is learning more now please contact the homeowner below.

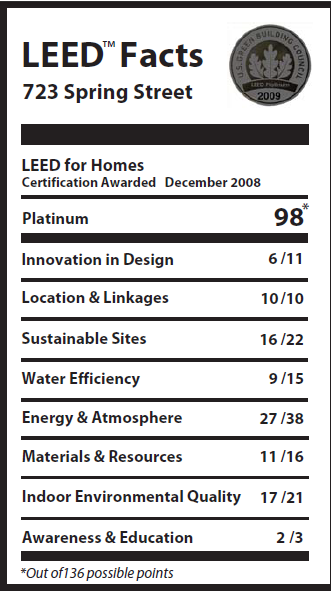

Scott Phillips, Associate at The Inovo Group and homeowner of Ann Arbor’s 1st LEED Certified Platinum Home is a passionate blogger about the success of green his certified home. Scott gives us a unique perspective of his home that was certified back in 2008. Beyond the requirements of LEED, Scott has installed 15kWs of Sunpower PV panels on his house and they have been near net-zero energy over the five month period since the install.

This video is a description of the benefits of living in a green home by the homeowners of 723 Spring Street, Scott & Linda Phillips. They discuss the positive life-style changes as well as the advantages of “living local” near down-town Ann Arbor. Scott and Linda talk about needing fewer cars, water conservation, indoor air quality and their aspiration to be a net-zero energy home soon.

“The project team started with a broad set of goals. Since these were spec homes, they needed to have market appeal – more square footage than the smaller homes in walking distance to downtown. At the same time, they needed to minimize footprint so that the lot would have lots of green space and areas for water infiltration. By building up and taking advantage of the long East/West axis of the lot, each home would have roof space to hold enough

solar panels to go net-zero. By creating open floor plans, the small footprints of the homes would be spacious and feel larger. Durability and excellent thermal performance would be addressed through a combination of Structural Insulated Panels (SIPs) and Insulated Concrete Forms (ICFs). The HVAC systems in the house would augment that performance and use the least amount of energy for the structure. To the extent possible, the significant non- invasive trees on the lot would be preserved. One last goal was to have the home fit in the neighborhood of older homes. By staggering the homes, we created more solar-gathering opportunities, and decreased the mass of the homes at the street. This helped the homes appear to be in scale, and by designing for the Victorian era, we were able to build in details that were similar to surrounding homes.”

“The location of our homes, downtown Ann Arbor, contributes significantly to the owners being able to live a low-carbon and healthy lifestyle. The homes are also very tight, and our duct leakage was virtually zero when tested before drywall. Good low-flow water fixtures and recirculating hot water save operational costs, as does the geothermal system. South side windows are 3 times the area of north-facing windows, and an ERV keeps the air fresh when the windows are closed.”

Builders: Meadowlark

You can follow along the journey and continued green success of the home at the follow websites…

The web-enabled Enphase Enlighten Monitoring constantly collects real-time PV system data transmitted from the PV system.

http://723springstreet.com/enphase-enlighten-monitoring-system-provides-real-time-pv-information/

http://723springstreet.com/enphase-enlighten-monitoring-system-provides-real-time-pv-information/

Illinois Net-Zero-Energy masterpiece producing 40 percent more energy than it consumes

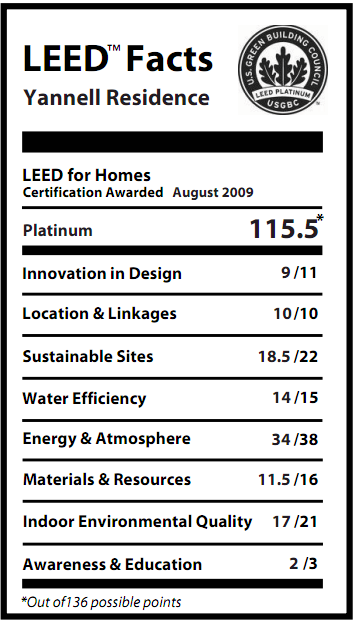

/8 Comments/in Illinois, LEED Platinum, Net Zero, Single-Family Projects, Zero Energy Capable/by Brett LittleStarting with an eco-conscious dream for a truly green home transformed owner Michael Yannell’s Chicago residence into a $1.6 million, two-story 2,675-square-foot, four bedroom and two-bath Net-Zero-Energy masterpiece, producing 40 percent more energy than it consumes.

Completed in 2009, it is not only Chicago’s first LEED Platinum-certified home, but it has scored higher than any other LEED-certified project in history. Architect Farr Associates, builder Goldberg General Contracting Inc. and engineering MEP firm dbHMS created this urban infill project to utilize aspects of alternative energies through passive solar, solar grid technology, a greywater system and closed looped geothermal heating and cooling components. According to owner Michael Yannell, the main goal of this project was to create a more energy- and water-efficient, environmentally conscious place to live and to set an example by building a home as sustainable as possible. Incidentally, the green materials generally were no more expensive than conventional alternatives.

This Net-Zero-Energy residence was built using the U.S. Green Building Council’s (USGBC) LEED for Homes Pilot Program regulations. In order to earn the coveted LEED Platinum-certification, a project must meet the 100-point requirement, in which the Yannell residence scored 115.5. According to Net-Zero statistics, the Yannell residence generates 18,000 kWh/yr and uses only 12, 689 kWh/yr, earning the Yannell property an approximate $52,000 in tax credits in 2008-2009.

According to Jonathon Boyer, principal and director of architecture for Farr Associates, the permit and design processes were a challenge from the beginning, but thanks to help from a hand-picked team, deadlines were met and the project was a success.

“We put together a team of engineers, contractors, and a landscape architect, and the entire project was a team effort,” Boyer said. “Building Net-Zero-Energy is very difficult, and it requires cooperation between all components and consultants. We believe we’ve broken the sound barrier with this house, especially in the Chicago area.”

This being the first LEED-certified home came with obstacles along the way. According to Boyer, by creating new systems such as the greywater system, which recycles water used from the washing machine for the toilets, it was tricky trying to solidify the permit process. It has opened up new options for Chicago to consider when building more sustainable homes.

“It was a learning process, the city of Chicago was open to it. We didn’t have any hard and clear standards in the city for permitting this kind of system,” Boyer explained. “As a result of this house, the city of Chicago Committee of Standards and Tests is adopting a new state / city code for rainwater / greywater reuse. “We were pioneers and induced the city to think about changing permits to use more sustainable elements into the residential market,” Boyer said.

Other than utilizing alternative energies, the Yannell residence’s modern design integrated into the traditional neighborhood fuses form with function in a dense infill space. The home was built on a recycled lot where the previous building could not be salvaged. Boyer explained that typically energy-efficient homes are bland and lack style, but in this case, the owner and the building team wanted something well-designed and unique.”He [owner, Michael Yannell] wanted

something aesthetically compelling and functional,” Boyer said.

The floor plan is designed as a dual-wing connected by a foyer, which acts as an entry and passageway, both equipped with south-facing windows to utilize natural light and garden views. The positioning of the wings help compete with the Midwestern climate year-round. With temperatures ranging from the high 90s in the summer to blistering zero-below winters, it was crucial to find the most sustainable design possible. Each wing has a uniquely shaped multi-functional V-shaped green-roof designed for stormwater management and for concealing the 48 photovoltaic grids on the home. “The

butterfly pattern roofs are designed to screen the solar panels from view, while providing an ideal angle for the panels to harness the sun’s energy,” Boyer said. Although the Yannell residence has received the highest LEED score, the materials it took to achieve the title are not unattainable for other eco-conscience projects. According to Boyer, “LEED for Homes is less than $3,000 for certification.” In this case, it assisted in the construction process by acting as a detailed guide when installing aspects such as air quality, water systems and when planning the positioning.

Although there is no set specific standard definition for a Net-Zero- Energy home, Boyer said that there are other homes out there that claims to be Net-Zer-Energy, but many have only lowered their energy consumption. Only the Yannell property has the data to back it up. According to Principal of MEP firm dbHMS, Sachin Anand, “It’s [the Yannell residence] the future of housing and power generation where each home is a greenhouse emission-free power plant.”

View LEED for Homes Project Profile

http://www.elledecor.com/image/tid/5950

Photography By Christopher Barrett. Evan Lancaster is an editorial assistant at Green Homebuilder magazine. He may be contacted at elancaster@penpubinc.com.

Built for the Future. The Yannell residence in Ravenswood, Ill., a traditional neighborhood outside of Chicago, breaks barriers of traditional homebuilding by perfecting green practices. From http://www.greenhomebuildermag.com/fall42.php

Menu

GreenHome Institute

GreenHome Institute

ATTN José Reyna

1451 Lake Drive SE, #6484

Grand Rapids, MI 49516

Tel: (616) 458-6733

Email: info@greenhomeinstitute.org

About Us

Recent Posts

- April 2024 GreenHome and Sustainability Jobs Round-Up.

- Protected: Public comment on Inflation Reduction Act Home Rebates opening in MI and beyond

- Shawn Neinhouse completed Certified GreenHome Professional Training

- Please take this MSU Student’s Mass Timber Survey

- Clean Energy Credit Union Clean Energy For All Reduces Barriers