Each week, we host a free CEU Webinar at noon EST, and many questions remain unanswered, so we invite the speaker(s) to follow up and address these questions.

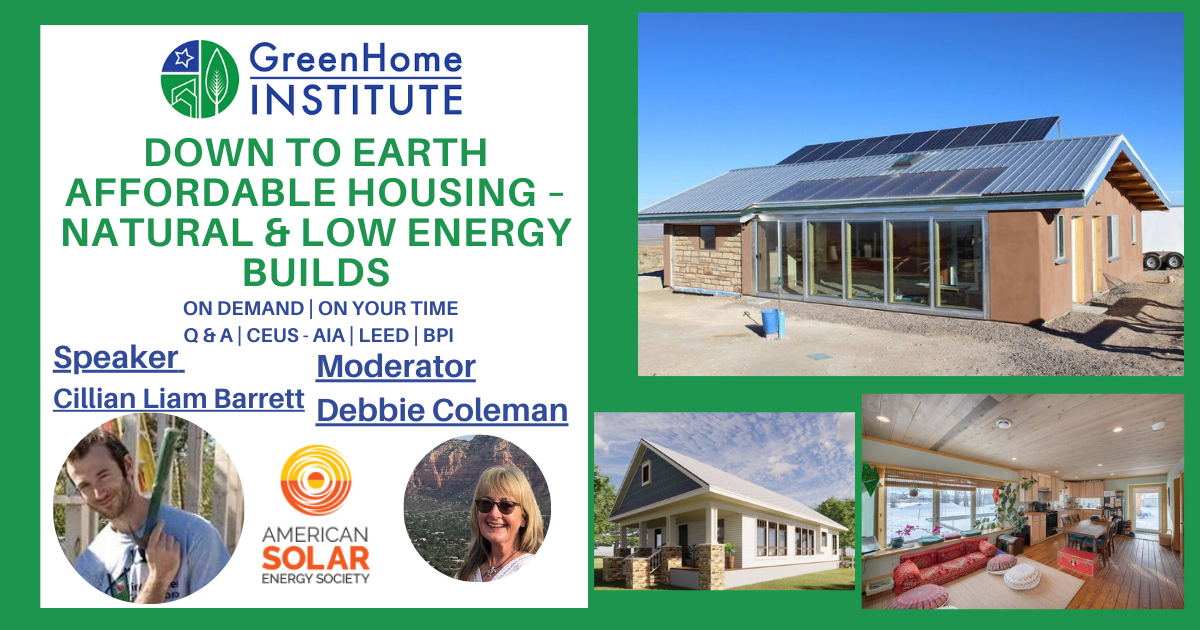

Here are the answers for Down to Earth Affordable Housing – Natural & Low Energy Builds

If you haven’t already watched the recording or attended live, please do so now and then review the questions below. You can still post additional questions right into our YouTube comments, and they may be answered. Need continuing education? Visit this link to watch the video and take the quiz.

Participants gained a rich understanding of sustainable building materials and techniques, especially the practical applications of straw bale construction, cork insulation, double stud walls, and vapor-open assemblies without sheathing. Many noted surprise and excitement about using natural, local, and low-carbon materials such as hemp, cork, and adobe in modern construction. Several appreciated learning cost-comparison insights, the design-build approach, and creative solutions like diagonal furring and homemade plaster panels. Participants were particularly inspired by real-world examples of affordable housing using ecological materials. As for lingering questions, respondents were curious about further implementation details, such as how to make plaster walls, feasibility of diagonal strapping in seismic zones, limiting subcontractor use for affordability, and understanding building code requirements versus alternative methods. Many also expressed a desire to volunteer, explore these methods further, and incorporate them into their own practices.

Question:

Hello, and thanks for presenting. Love the idea of straw bale and alternative wall systems, but the worry about air-tightness and moisture management always rears its head. Could you explain what steps you take in this type of construction to mitigate those issues?

Answer:

Straw is mainly composed of cellulose and lignin. It is basically the same as make up as wood, hemp, paper but at different densities. You take the same preparation you would for any natural material or any building. The only different is that failures happen faster with less dense material such as straw. Straw bale and natural finder based structures fail because of poor detailing and construction precaution, not because of the material. These problems are very common on conventional building sites and designs too. Keeping any natural fiber based materials 12” above grade is the first step, and then detailing well for bulk moisture (roofs, flashing, plumbing leaks, etc). Air tightness with straw bale can be achieved with a smart vapor barrier or with detailing the plaster with “plaster fins” so cracks don’t compromise the air control layer.

Question:

How do you make your own cement boards? Answer:

We made our on “ClayWall” Panels using 24x48x3/4” flat forms. We laid in burlap as a skin

and then added the clay/adobe plaster mix just like you would do for baking brownies. Then it would dry in a rack for 2-4 days.

Question:

What kind of window performance do you try to get with these buildings? double pane? triple pane?

We only use “Passive House” certified windows and doors [PHI or PHIUS]. That guarantees a performance level and I don’t have to even think about. There is no other standard in the USA that I trust.

Question:

Let’s try to get PVCs out of our interiors in these projects, you’re compromising your IAQ Answer:

I agree about using or eliminating PVC from construction but it is very challenging. I have

built a home that was 99% PVC but there is a lot of extra cost and time. PVC is in so many products including the ones homeowners will fill their home with after you are finished.

Plumbing and electrical is peppered with PVC. There is a premium cost for other materials for windows unfortunately. We try to use Fiberglass windows instead or on high end projects, natural wood. Regarding IAQ, our monitoring has shown no evidence of

off-gassing form PVC but then we are probably not looking deeply enough. I am not aware of a specific way to monitor that. Fire and PVC is the main danger I am aware of. The health and safety of firefighters is certainly something we consider in our material choices.

Question:

How did you handle shear during construction before installing the diagonal strapping? Answer:

Temporary interior bracing

Question:

What was the CFM leakage of building envelope? I know ACH is used for compliance, but I prefer the envelope leakage rate

Answer:

70 cfm

Question:

Could you elaborate on the best practices for connecting an external strawbale wall to an internal framed wall?

Answer:

Plastic baling strap. I will add: I would put the bale on the inside and have the less durable plaster on the exterior. Exterior plaster requires maintenance and can only be installed 6 months of the year in our climate. With the plaster to the interior, you can also do a range of conventional finishes on a rainscreen on the exterior and plaster indoors all year round.

Question:

Was the laundry tambour door custom-made or a commercial product? Answer:

Donated! We got lucky

Question:

Do u have a $/sq ft cost for these houses and a $/sqft operating cost? Answer:

This is a common question and one that is very hard to answer. Typically the person asking

is trying to figure out if they can afford to build like this and compare it to conventional construction costs. There are SOOOO many variables (on any construction project) and it is very site and resource specific. This was a Habitat for Humanity build so most of the labor was free but unskilled. We attempted to track hours (and skill level factor) so we could answer these questions. We had limited success. If you have a particular project in mind, please contact me for guidance. Having said that, this house was 960 sq ft and it cost the homeowner $210k. So $2.18 per sqft. In 2019. Without land value included. If we were to build this house today, for market rate, using our systems and Design/Build integration process, I would guess; without land, in a city with utilities at the property line, in our current industrial climate, $400-500 per sqft. That is specific to Gunnison, Colorado. If I was to build in Crested Butte, 20 miles up the road, I would say $800 per square foot. It is that site specific.

Question:

Why no pv on main roof on hopi project? Answer:

There is a 5kw system on that roof but perhaps not at the time that picture you seen was

taken. It also has as a homemade solar thermal how water panel made from a recycled HWH tank, patio door and cork insulation. It provides the hot water 8-10 months of the year. There is a supplemental electric on demand HWH or back up .

Question:

Looks like mento membrane is applied directly onto studs? Then covered w/ layer of 45° furring strips. Any concerns of membrane tearing w/ no sheathing layer supporting it (especially during construction)? How to 45° furring strips provide ventilation / drainage plane behind cladding – are they perforated?

Answer:

Definitely a concern with tearing during construction and I would not specify it unless it was a crew who understood to report accidental penetrations or better yet, fix them. We put self selfing tape under each screw. The 45 degree braces do not have drainage behind because the amount of water that could penetrate and run down that plane is negotiable and the wood will dry quickly behind that well vented rainscreen cavity. If you were concerned you could simply add a vertical spacer batten on the inside in the center of the bay to allow for a large continues quantity for bulk moisture. It that situation, I would have other concerns! Are you thinking driving rain in coastal Maine?!

Question:

Have Cillian and other folks on the call seen or heard of prefabricated straw-panel walls being imported to the United States through the design and build, consulting firm BuildWithNature.us ?

Answer:

There are a few in Europe but now also some available in the USA. A great resource for that is “Builders For Climate Action” and New Frameworks: https://www.newframeworks.com/ They are teaching people how to start their own straw panel businesses! Importing straw bale panels from Europe is insane in my opinion. A good first step to make them available but the local industry has a huge opportunity if there is a market for that.

Question:

This stone work on the Hopi project are beautiful Answer:

I know, they are very talented folks! Hand quarried.

Question:

Any mass in hopi project? Answer:

Lots of thermal mass in the adobe floor and the adobe/stone walls

Question:

Is the kitchen in the hopi project concrete? Answer:

Yes, it’s a site built concrete countertop. Personally, I think a local lumber wooden

countertop is a lot less work, lower impact and reusable. I also don’t love the aesthetic but that’s a personal preference.

Question:

How do you avoid pressure treated lumber where walls meet concrete foundations or slabs?

Answer:

Plastic or metal flashing capillary breaks. Non porous stone can work too, just like in the old days! Sills were typically granite of dance stone in historic construction. Concrete is porous and that was the reason PT lumber was invented.

Question:

Induction stoves are up to 10% more efficient than conventional electric ranges + can boil water 20-40% faster (See EnergyStar) The responsive control of the induction stove is critical for transitioning the culinary industry to a low carbon future.

As Rewiring America notes, 90% of induction stove heat transfers to cookware (only 74% conventional elec. stove)

REFERENCES:

Chef Christopher Galarza

https://www.linkedin.com/in/chef-christopher-galarza-cec-cca-ecc-wcec-8a632742/ Rewiring America:

https://homes.rewiringamerica.org/articles/induction/induction-stoves-vs-electric-stoves EnergyStar:

https://www.energy.gov/articles/making-switch-induction-stoves-or-cooktops#:~:text=Inducti on%20appliances%20are%20up%20to,pollution%20associated%20with%20energy%20gen eration.

Answer:

Induction is great way to cook but not a huge energy saver. An extra PV solar panel easily offsets its impact and is a better use of money, currently.

Question:

In general, is it easy nowadays to find reclaimed materials? Has an industry spring up that reclaims materials?

Answer:

Typical reclaimed materials is an expensive and boutique industry. In my experience, it is not a big solution for reducing environmental impact. We need to look at large systems and how to redirect the impact of the construction industry as a whole. Materials & Practices that store carbon

Question:

Please Name the Window Company you claim as R-7. Answer:

FG windows; “Zenith” from Alpen Windows. Tyrol PVC doors (They don’t make a FG door

unfortunately)

Question:

Could you provide some information on where to source the cork insulation you used? Answer:

Small Planet Supply (West Coast). Great folks! Cork is fantastic but it is expensive. I wish

there were cork forest anywhere they could grow! East coast: Eco Supply Center Question:

Could you speak more about the 1st house strawbale + framed wall? [see G.T. question, above]

+

Could you speak more / share detail for window thermally broken with cork? [several homes discussed including last Granville, Vermont]

Answer:

2×6 (full size rough cut lumber) load bearing exterior wall with cellulose insulation [R-21] and 14” straw bale [R-30] with let in interior stud for lath and opening support. The cork is a thermal break between the exterior leaf of the double stud and the intro leaf. I don’t think it is really that necessary if you have a vapor open, super airtight envelope strategy.

Question:

Do you have a course and book available for purchase concerning affordable housing with Earth?

Answer:

I personally am unpublished! There are many books out there but I would need specific to guide you in any particular way. I am happy to consult on projects with folks who values align. The Natural Building Companion (Ace & Deva) & Building Better Buildings (Chris Magwood) are great all around.

Question:

Is the greenhouse space on that one house considered part of the conditioned envelope? If not, could one draw fresh air from the greenhouse as a pre-conditioner for an ERV?

Answer:

Great Question! It’s a bit of a blurred line. I was working with the HTP’s previous building strategy which did not at all account of air leakage or vapor barrier. I would cautiously say; “yes”…

Question:

Do you have any performance data (operational energy + embodied carbon) comparing Pikes Peak, CO 2×6 cavity insulation + exterior R-10 vs. Gunnison, CO strawbale + framed/cellulose?

Answer:

That’s a deep question with lots of variables. Good place to start is to find the Heating degree days [HDD]. It’s the easiest way to compare heating requirements for a particular climate. heating degree days.net. Skip to the end: we need to storage as much carbon as possible every chance we get. We don’t always “Need” passive house levels of insulation but that’s our best chance to reduce and potentially even reverse cabron impact. I would have to evaluate your specific situation to give a better answer.

Question:

How does the straw bale breathe with an exterior air / moisture barrier? I have only used bale in a breathing wall application, with air barrier only in the past

Answer:

When we say “breathable” wall, we are talking about two different things. A wall does not breath. People do and they need to breath inside our buildings. We need intentional mechanical ventilation in our buildings to be able to control what we breath (think forest fires and air borne viruses). I think you are referring to “perimbility”, meaning the rate at which water vapor specifically can pass through a material or an item. A wall needs to be designed and constructed in such a way that moisture behavior is considered and predicted. Air tightness is the best guarantee of restricting moisture from entering your wall. Having vapor open materials and barrier in that wall (in a dry climate) is the best way to insure long term durability. Avoiding thermal bridging and condensation is important but less so if all you materials can get wet AND dry easily. In our envelope, the exterior of the envelope has “Mento” air control layer which has a permeability rating [Perms] of 40. That is a very high drying potential. By comparison, plywood is general considered 8 perms and OSB less and 1. In hot/wet/cold climates (think North Carolina), you must think about how to keep vapor out of your envelope/house from the OUTSIDE climate in the summer as your AC will create a drier climate inside and thus wet wants to go to dry.

Question:

Up to 10% savings ( that’s my point is overhyped) on induction generally not worth it especially if u have elec stove. may b worth it for replacing gas for a variety of reasons on new const maybe ok if u can put up with probs and don’t want a reused coil elec stove

Answer:

See above. In my opinion, not a 1,000 gorilla. Definitely replace gas with electric for IAQ reasons

Question:

What is a good (or the best) way to incorporate continuous exterior insulation withOUT using foam? What environmentally friendly or sustainable product(s) are recommended? I know Rockwool is carbon intensive. Thank you.

Answer:

No great solutions that are affordable. The process of wrapping your building with exterior insulation is a labor problem. Double stud construction passes for continuous insulation. I don’t know of a cheaper, faster, lower carbon way to build a high performance wall. Thick walls with natural finders equal carbon sequestion. More the better! If Hubbard started making a high perm, formaldehyde free plywood sheathing panel with R-5 natural fiber insulation attached to it, that would be a great start! Vapor open, thermally broken carbon neutral sheathing ready for taping. Imagine that!

Question:

What do you think about buying down a soft-second mortgage? Have you used that before? Answer:

I don’t know what that is. If you are referring to a revived recent trend of bundling a

construction loan for energy upgrades into your utility bill, I say RUN AWAY!