| Give us success stories as well as lessons learned | |

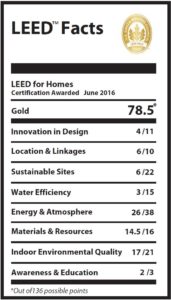

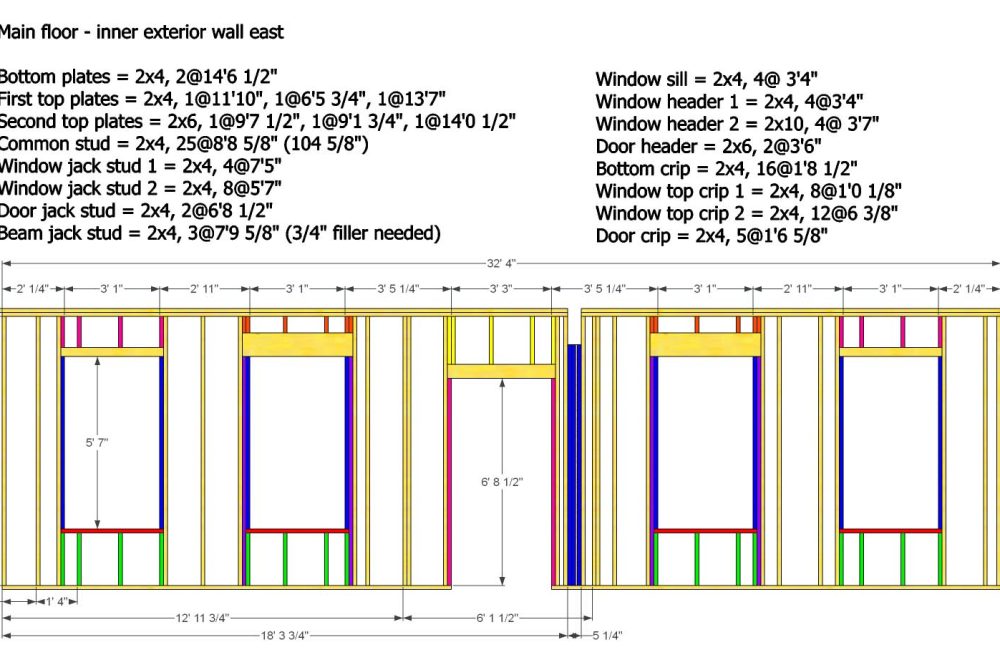

| While there are many alternative systems and materials available to aid in the construction of a home, sticking with more traditional foundation and framing methods allows for workers to more easily adapt to the simple changes necessary to produce a highly insulated and airtight building envelope.Our projects are always design driven. We produce a complete 3D model of our projects down to the studs which allows us to achieve a very high level of accuracy and avoid problems that can arise during construction. Proof of this is in the numbers. By focusing on airtight construction during the design and throughout the framing process we were able to produce a shell with an air exchange rate of 0.58 ACH. By having extremely accurate material take offs, we succeeded in producing only 12 cubic yards of waste during the entire build. Our detailed design work also allowed us to control costs and produce a home with a HERS score of 32, LEED gold certification, and a square footage cost in line with average costs of standard new construction. | |

| Tell us what is unique or innovative about this project | |

| 10″ thick thermally isolated double studded exterior walls to provide insulation value of R-40 Both passive heating and cooling designs Active heating and cooling for the entire house is provided by two Mitsubishi mini-split units (total heat loss calculation = 22,737 BTUH) Numerous universal design features including a zero clearance entry, an elevator shaft, and wide doorways and hallways |

|

| Any special thermal envelope, insulation or passive heating & cooling details? | |

| Insulation strategy: basement slab R-20, basement walls R-30, above grade walls R-40, ceiling R-60 Airtight construction resulting in an air exchange rate of 0.58 ACH50 Large cupola on top of house has remote controlled windows to provide for passive cooling design House is oriented within 10 degrees of true south, with high solar heat gain coefficient windows on the south side for passive solar heating |

|

| Any special HVAC systems worth mentioning? Describe them | |

| All heating and cooling is provided by two 18,000 BTU Mitsubishi hyper-heat mini-split heat pumps Balanced continuous ventilation is provided by UltimateAir 200DX RecoupAerator ERV |

|

| Explain your water conversation strategies | |

| The plumbing system is a structured design with remote manifolds and recirculation loops for the hot water, manually controlled by pumps. All hot water pipes are insulated to R5 to reduce heat loss. This setup allows for hot water to be delivered on demand without the need to run the faucet to flush cold water from the pipes. All lavatory faucets and toilets meet the EPA WaterSense criteria. An Energy Star rated washing machine with a WCF of 3.6 and an Energy Star rated dishwasher with a water usage rate of 2.9 gallons per cycle were both installed. | |

| Explain your materials & durability strategies | |

| Our primary material and durability strategy revolves around efficiency, ease of maintenance, and environmental considerations. The green merits of many material choices can be debated regarding their material content, carbon footprint, and expected life cycle; but ultimately the realities of construction will result in compromise.Good design and planning results in greater efficiency and the efficiently used material is the most environmentally conscious material. Regardless of what materials you use, if you are filling dumpsters with the cut offs and scraps you’re missing the bigger picture. For example, we designed the bedrooms to be 12′ wide. We knew we wanted to put carpet in these rooms and carpet comes in 12′ rolls. Doing so virtually eliminates any waste. Sure there are carpets that have recycled content (which we used) and/or end of life recycling, but even if you recycle the waste you’ve still created more negative environmental impacts than needed. The mantra “reduce, reuse, recycle” is worded in that order for a reason. Reduction is always preferred. Waste is more than the unusable excess material left over. It is the environmental costs of production, shipping, and even if you recycle the excess there is a cost to that as well. Our whole house was designed with these material efficiencies in mind.

A key factor to durability is the potential ongoing maintenance that may be required. All homes require maintenance, but the reality is that most homeowners fail to keep up with these requirements. By choosing materials that require little or no maintenance we can significantly reduce the greatest impediment to the durability of a house – neglect. Lastly there will always be materials used in construction that will have negative environmental considerations. Ironically some of the most durable materials are also the most environmentally negative. We used a lot of XPS insulation to insulate the below grade portions of this house. It is not recyclable and is produced with harmful blowing agents; but in this particular application it is an excellent choice. It is an excellent insulator, does not support mold or mildew growth, does not absorb moisture and will last forever. However, this is one of the only places we used this product in our house. All of the above grade insulation is cellulose, which is made of a high volume of recycle content, is reusable, and has a very low embodied energy from production; making it the most environmentally conscious choice. |

|

| Detail the health and indoor environmental quality benefits | |

| Always choosing low VOC materials is a requirement for us. The indoor air quality will always be affected by the materials inside the home. This is the easy part to address; but what about the contaminants from the outdoor environment that are introduced? Uncontrolled air infiltration brings pollutants with it. That is why it is so important to control how the indoor and outdoor air is exchanged.By constructing an extremely airtight shell, we virtually eliminate uncontrolled air exchange. A home needs fresh air, but now we control how that air is delivered. Through the use of a continuously operated ventilation system we are constantly providing fresh air to all living areas of the home but not before passing that air through a MERV 12 filter capable of eliminating dust, mold spores, and pollen.

Another feature of this home is the use of an enclosed breezeway connecting the house to the garage. This creates an “airlock” that prevents garage contaminants from seeping into the house as well as provide a place to remove dirty shoes to prevent tracking contaminants into the home. |

|

| Tell us about your place or location statagies | |

| This home was built on a vacant lot in an established neighborhood. This allowed us to connect to existing infrastructure without contributing to urban sprawl. The location is within a 1/4 mile of many basic community resources (including churches, schools, and a public bus stop) and within 1 1/2 miles of a major shopping corridor that has banks, gas stations, a major home improvement store, grocery store, and much more. In addition the location is within walking distance of a network of hiking trails.While many people prefer to have some space in the country, we believe that closer proximity to community resources is the more environmentally conscious choice. Careful lot selection and subsequent development can still provide the privacy and closeness to nature while at the same time reducing transportation costs and impacts. | |

| What else should we know? | |

| Building a green home is as much about the process as the resulting product. Home construction is a resource intensive operation, and as such the impacts are more a function of the methods and design than they are about materials. More and more builders are recognizing the value of a green built home, but many of them are missing the bigger picture. While using more environmentally conscious materials is a good first step, truly changing your methods and designs will have the greater impact. A well designed and built energy efficient home will stand the test of time and be functional and enjoyable for generations to come. Reducing both the environmental impacts of the initial construction and the necessary ongoing resource consumption is what truly makes a home green. | |

Project Team Details

The design and build were completed primarily by GC/Homeowner Paul Abueva whose company Abueva Builders LLC was responsible for all drawings, systems designs and calculations, and the majority of physical construction other than the following work performed by sub-contractors:

* Foundation and septic system – Powell Custom Homes

* Electrical – Bright Ideas Electric LLC

* Insulation – Spartan Insulation and Coatings Company

* Drywall – Midwest Wall & Ceiling LLC

* Mini-splits – Suburban Heating and Air Conditioning

* Landscaping – J.D. Vlietstra Company

* LEED Green Rater – Michael Holcomb

Project Basics

3 bedroom, 2 1/2 bath, 1124 square foot basement, 2182 square feet of conditioned living space, detached 2 car garage with connecting enclosed breezeway and 350 square foot bonus space above the garage. New Construction.

Project Certification Details

Certification Program: LEED for Homes

Level: Gold

Cost per square foot $170.00