| Give a summary of the project | |

| THE 2100 is a 97-unit luxury apartment project that was completed in March of 2018. It includes four stories of apartments built on top of two floors of structured parking. The site area is 1.42 acres. The unit mix includes studio, one, and two-bedroom units. The project is an infill project that involved re-use of a site formerly improved with a functionally obsolete first-generation suburban office building. | |

| Give us success stories as well as lessons learned | |

| There were a number of hurdles that had to be cleared to make the project a success. The site is on a major thoroughfare but is also next to a residential neighborhood. The development team worked closely with the City of Wauwatosa to account for neighborhood concerns to achieve success in getting the site rezoned. The existing building on the site had to be razed, which required navigating through some minor environmental clean-up. The City required improvement of access infrastructure as part of the project, so the development team worked with the City to structure TIF funding to make this feasible. Project funding was achieved by obtaining a mortgage insurance commitment via HUD’s 221(d)(4) program, which had some incentives for green construction. This was not an easy project! The main lessons learned included the need for patience and perseverance to get something like this done, along with having a good team with the right people. | |

| Tell us what is unique or innovative about this project | |

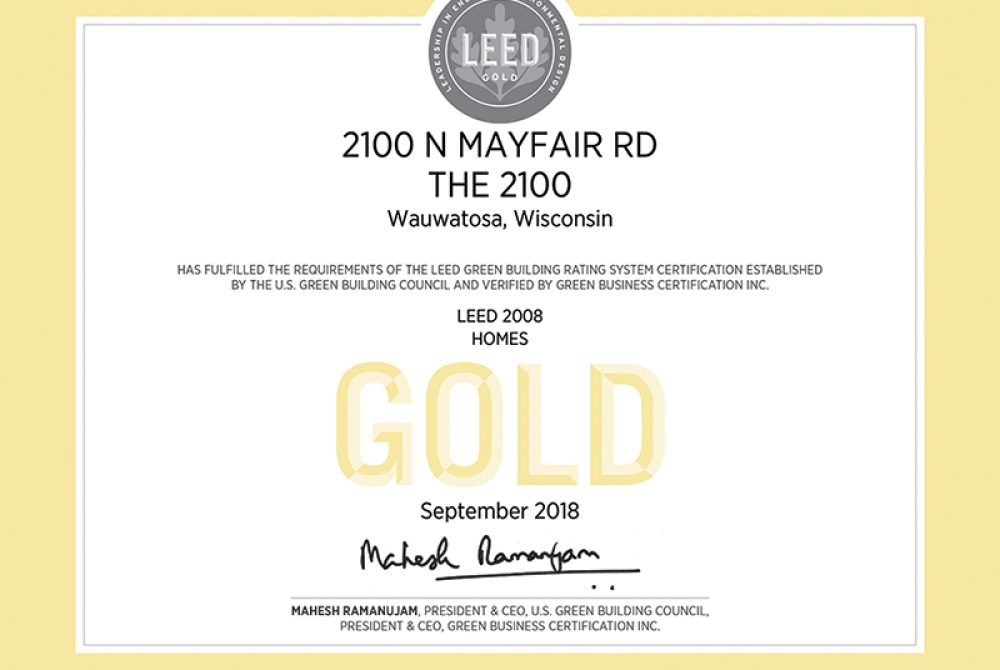

| THE 2100 is only the third market-rate apartment project in the Metro Milwaukee Area to receive LEED certification and is the first such suburban project. It involved re-use of a more difficult in-fill site in somewhat of a pioneering location. Building design had to account for the high-traffic location on Mayfair Road as well the adjoining residential neighborhood. Features to address the former included a high noise attenuation window system, a denser wall system, and extensive use of sound and thermal insulation. The neighborhood side of the site was extensively landscaped to soften building impact. An extra parcel of land was purchased adjacent to the building delivery doors for truck and delivery parking to minimize any inconvenience to neighbors. The project has unique features like electric car charging stations and green infrastructure features (e.g. green roof). | |

| Any special thermal envelop, insulation or passive heating & cooling details? | |

| We believe part of the LEED approach is quality. A LEED-certified project is simply a better-quality project. We elected to use a wall system that made extensive use of Nichiha architectural panels with the balance of brick and decorative CMU’s. The framing is all 2″X6″ with extensive insulation. We also used a high noise attenuation window system for superior sound insulation qualities. | |

| Any special HVAC systems worth mentioning? Describe them | |

| Units all have individual HVAC units rated as having exceptional energy efficiency. In addition, all units have programmable thermostats to allow customized set-back on heat or cooling for energy savings. | |

| Explain your water conservation strategies | |

| Our water strategies are twofold. As far as domestic water use, all fixtures and fittings are high-efficiency. This applies to our site landscaping irrigation as well. In addition, THE 2100 received recognition from the Milwaukee Metropolitan Sewerage district for its stormwater management features in the form of a green infrastructure grant. Such features include a green roof over part of the structured parking, use of porous pavers, a bioswale, and use of “thirsty” native plant species for landscaping. | |

| Explain your materials & durability strategies | |

| Materials strategies included off-site framing assembly in a factory environment, which greatly reduced waste. Environmentally preferable materials were used wherever practicable. The exterior wall system of Nichiha panels and masonry is a heavy-duty, durable system. Parking lot paving is concrete as opposed to asphalt. The green roof has an electronic leak detection system “just in case” to deal with any problems in a manner to minimize overall system disturbance if a repair is needed. The building participates in local recycling as part of its trash collection. The site itself is, in effect, recycled since it involved redevelopment of a site previously improved with a first-generation suburban office building. | |

| Detail the health and indoor environmental quality benefits | |

| Materials used (e.g. flooring, paints, etc.) were environmentally preferable where possible to minimize or eliminate off-gassing, VOC issues, etc. Sustainable sourcing was also used where possible (e.g. bamboo flooring in common areas). Air infiltration and Indoor air flow are items monitored and graded during the LEED rating process and THE 2100 passed with flying colors. | |

| Tell us about your place or location strategies | |

| The site of THE 2100 is an infill site involving redevelopment of that site to a higher and better use that is more sustainable. It is located at the geographic center of the Metro Milwaukee area. It is in a high-traffic location with access to public transportation that is two blocks south of the Milwaukee Area’s premier regional mall. In addition, a node that includes the Milwaukee Regional Medical Center (consortium of six healthcare institutions employing 16,000 people), the Milwaukee County Research Park (two million SF of offices, 4,500 employees, home to GE Healthcare’s US HQ, etc.), and the University of Wisconsin’s Innovation Campus is within five minutes of THE 2100. However, the site also abuts a residential neighborhood. Thus, the location has urban amenities (e.g. complete array of shopping opportunities and entertainment venues, public transport, easy access to employment centers,etc.) but yet there is a natural parkway with a creek within a half-block. Location strategy? Simply to take advantage of these location attributes with a sustainable project that is a worthy addition to the community and surrounding neighborhood. | |