| Give a summary of the project | |

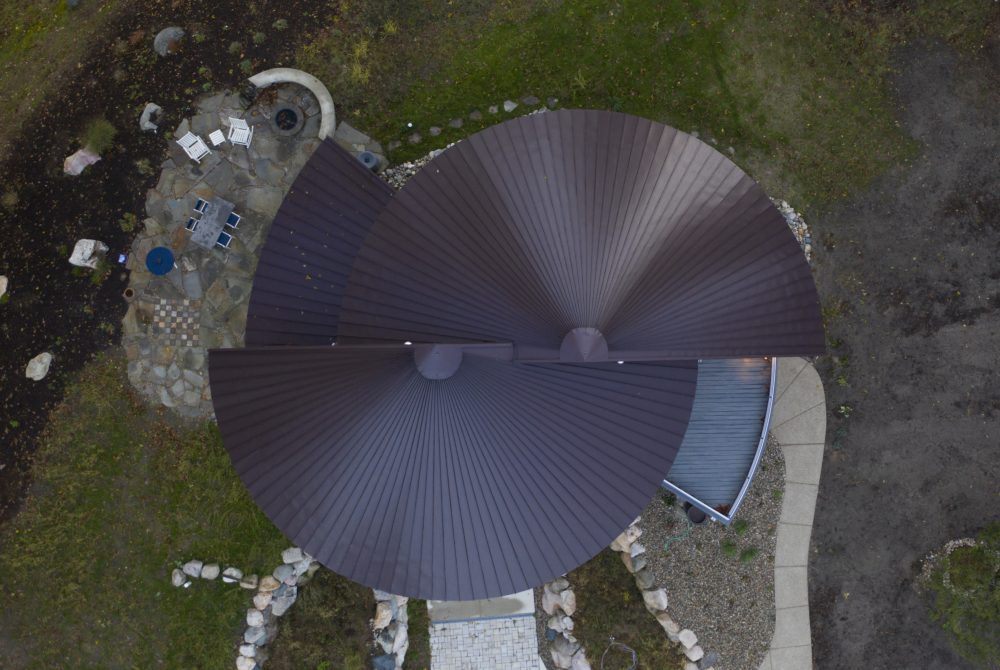

| The owner of this new home is a life-long resident of SW Michigan. Frustrated with the limitations of attempting to upgrade the energy efficiency of a 1950’s era ranch home, this environmentalist decided to “do it right” and build an energy efficient & eco-friendly dream home. After much research, the decision was made to pursue a “net-zero home”, meaning the house will generate all the clean renewable energy on site to power itself year-round. Zero fossil fuel burning, means no more pollution or green house gases which is the mission of Passive Building, to get the building sector to reduce it’s impact in our race with global warming.With lake views to the north and solar gain to the south, this wooded site was challenging to optimize window orientation and solar panels to these conflicting orientations. Yet, the design solution achieved stunning lake views from the primary “day spaces” as well as the master bedroom. Excellent solar gains from the second floor’s abundant south facing glazing with the perfectly dimensioned roof overhang shading the windows in the peak summer months. Computer animated modeling of the trees on the site allowed for optimum placement of the house and solar array.

The home’s curving floor plans are a metaphor for themes of contemplation, transformation and a healthy flow of what’s known in eastern cultures as ki (chi) or “life energy” valued by the owner. Circulating through the homes two floors and thermally isolated basement level garage via it’s stunning curved open riser staircases provides the feeling of living in a treehouse in nature. The home is designed with “Aging-In-Place” principles; is wheelchair friendly providing complete living services on the first level and is designed to accommodate installation of a vertical lift to the basement should it ever become needed. The architect chose Passive House design principles knowing it’s the best start to any net zero project by minimizing energy demand. 15″ thick double stud walls (R-60) filled with eco-friendly cellulose insulation. 24″ deep TJI’s at 24″ o.c. ceiling joists with high density cellulose provide an R-100 cap to the conditioned space with the attic strategically outside of the thermal envelope. In fact the entire home is virtually foam free as eco-friendly material selection was important to the project team. The few trees that had to be removed from the house footprint, were milled and kiln dried locally and used for all the hardwood flooring throughout and many of the cabinet faces. The home achieved it’s goals of being “Net Zero”; a certified Passive House while earning LEED’s highest rating of a Platinum level for sustainability and eco-friendliness. |

|

| Give us success stories as well as lessons learned | |

| The home’s strategic and well planned design and detailing has achieved multiple certifications: It’s the state of Michigan’s first GHI Zero Energy Certified, PHIUS Certified Passive House + with PHIUS Source Zero Certification. It also achieved LEED’s highest rating of a Platinum level for sustainability and eco-friendliness. PH Certification includes: Energy Star Certification; EPA’s Indoor Air Plus Certification and US DOE’s Zero Ready Home Certification. The home was recently awarded the USGBC-SM’s “Innovative Project of the Year” award and is arguably the most energy efficient home in the entire State of Michigan.Some of the unique skills Abueva Builder’s brought to the project include: experience building super-insulated double stud wall assemblies; attention to detail in constructing an air-tight shell (the home achieved an impressive 0.04 CFM50/sq. ft blower door test); an eco-conscious mantra of “no waste”, attempting to use every waste scrap of material in the project and thus the project never needed a dumpster.

Aging In Place: The home is completely barrier free and wheelchair friendly. All living functions can happen on the first floor level: living, dining, sleeping, entertaining, bathing, clothes washing, etc. In the center of the home, the floor is constructed to pop-out to allow the installation of a vertical platform lift to go from first floor to basement garage level, should it ever be needed. Electrics are in place. Lessons learned include: • Site selection has a big impact on the architectural design of an energy efficient home. An abundance of trees and a strong site feature of lake views to the north made it challenging on window placement, which prefers facing south. If the site was on the other side of the lake, solar gain orientation and site views of the lake would have been the same. • The project started out with a detached two car garage with a shed roof loaded with south facing solar panels. At the last minute the owner decided an attached garage would be better, so the house was re-designed to move the garage function to the basement level. We weren’t 100% sure on how air and it’s relative humidity would behave throughout the year in the garage. Exhaust fans and an outside air intake were installed on opposite ends of the garage. A 2″ layer of rigid insulation outside the foundation wall was added. The interior performed fine throughout most of the year, but peak summer months with high RH would effect the interior when the garage door was left open for too long. Lesson learned was to include a central dehumidifier for the basement level garage for those few months. The exterior finishes are maintenance free |

|

| Tell us what is unique or innovative about this project | |

| The most obvious unique element about this particular project is it’s round form. In fact it’s the only round passive house in North America! All previous passive house designs tend to be very “boxy”. Due to the site having wonderful views 360 degrees around, and a home owner who values the spiritual, a round form embodied the spirit of site and home owner. There is a great sense of “flow” walking through the house which also welcomes natural ventilation throughout.The 15″thick double stud wall assembly; 24″ TJI attic floor and first floor framing allowed the use of eco-friendly high density insulation for the mass majority of insulation for the whole project. Foam was avoided as much as possible.

The few trees which had to come down for the project were brought to a local sawmill, cut and dried to be used for all the home’s hardwood flooring needs and be the cabinet door faces, talk about locally sourced materials! The HVAC uses 1 efficient Mitsubishi ducted mini split system following the passive house philosophy of a 1 conditioned zone. Incorporated for superior fresh air is a Conditioning Energy Recover Ventilator by Build Equinox CERV2 with a unique ground loop heat exchanger. The system is the only one on the market with an ultra-violet light accessory that kills air borne viruses like Covid-19. HVAC, CERV2 and Hybrid hot water systems all use energy efficient heat pump technology. SOLAR POWER |

|

| Any special thermal envelop, insulation or passive heating & cooling details? | |

| ENVELOPE • Double stud wall technique w/15″ total cavity depth for super insulation and thermal bridge free construction, using curved plywood plates cut on a CNC machine for accuracy and to reduce material waste. • Triple pane high performance “tilt and turn” European style windows, assembled in the US exceed code compliant windows for U-value and air-tightness (U=0.16). SHGC changed for maximum efficiency based on each window’s orientation. Quadruple pain high-performance entry doors with a U=0.16 with four layers of gasketing for superior air-tightness for this “snow-belt” project siteINSULATION Virtually foam free project using high-density cellulose to close the recycling loop and for it’s eco-friendliness and affordability. Used in: Walls-R-50 Garage ceiling-R-54 Attic floor-R-90 2.5 x’s code levels for “Super-Insulation” high-performance. The fewer Btu’s that escape, the less the furnace has to run to replenish the loss, is the PH mantra.AIR-TIGHTNESS The builder has experience framing for air-tightness. All plates are set with beads of acoustical sealant to stop air-infiltration. Beads of sealant used at each step, throughout framing process. Tops of walls have a unique 3/4″ plywood layer that cantilevers 3″ to the interior. Ceilings are furred with 1×2 strips @ 24″ o,c. allowing netted high density super-insulation to buldge as needed, yet provide a flat ceiling. Drywall can be sealed to plywood plate making an air-tight transition from walls to ceilings. Air-tight drywall installation techniques used to provide an additional layer of air-tightness from the exterior sheathing layer (strategic redundancy), the project was blower door tested at 0.04 CFM/sq. ft.! • 1/2″ zip sheathing w/taped seams for walls and taped plywood seams at attic floor. • All pipe penetrations with rubber gaskets to air-tight sheathing layer. Limited number of holes: All holes approved by architect.THERMAL BRIDGE FREE CONSTRUCTION • Double stud walls eliminate thermal bridges in walls • Use of TJI’s for garage ceiling and attic floors stop thermal bridging. • Framing designed to stop thermal bridging on all parts of thermal envelope • High performance windows with insulated spacers and multiple air chambers in framePASSIVE HEAT AND COOLING • Roof overhang calculated to shade south facing windows in the summer perfectly • The location of the front and rear entries, along with the shape of the curved walls, provides excellent natural ventilation during the warm parts of the year. The curved shape also channels cold winter winds around the house rather than getting hit straight on like most homes. • Computer modeling determined the best site location for solar gain for the home and solar array. |

|

| Any special HVAC systems worth mentioning? Describe them | |

| SUPERIOR INDOOR AIR QUALITY • The heart of the indoor air quality is the integration of a Conditioning Energy Recovery Ventilator (CERV) from Build Equinox. It has four modes of operation based on monitoring CO2, VOC and temperature in the home for maximum fresh air and energy efficiency. The unit saves over 75% of the outgoing energy in the exhaust air stream. • A ground source loop heat exchanger uses the grounds temperature to pre-heat or pre-cool the incoming outdoor air. A pex tube was installed around the foundations footing before back-fill. For parts of the year, only the CERV is needed to heat and cool the home! • The system is the only one on the market with an ultra-violet light accessory that kills air borne viruses like Covid-19. |

|

| Explain your water conservation strategies | |

| WATER CONSERVATION • Dual flush, low flow toilets with unique hand washing stations on top of tanks, used during tank refilling • Lake is used to store rain water. A pump from lake is used for irrigation • Rheem Hybrid (heat pump) water heater unit with a hot water loop throughout the home and a hot water boost button located in bathrooms and at the kitchen, to conserve hot water. |

|

| Explain your materials & durability strategies | |

| • All exterior finish materials are low to no Maintainance and chosen for longevity and durability: metal roofing and metal wall panels are the majority of the exterior facade. • Concrete countertops will last the life of the home Hardwood flooring and cabinet faces fabricated from trees from the site, locally. |

|

| Detail the health and indoor environmental quality benefits | |

| • Superior indoor air quality with CO2 and VOC monitoring through the CERV2. The CERV adjusts it’s function based on measured conditions and responds accordingly. • All natural hardwood flooring used throughout. No carpeting. • All adhesives and paints used were no or low VOC products • Water filtration integrated with kitchen sink No fireplace, no gas appliances |

|

| Tell us about your place or location stratagies | |

| “Balance” is the key word to use for location strategies. Having a north facing lake view; south solar gain desired orientation and many trees on the site, one design could not satisfy all of these opposing conditions. Strategic design of the interior “day” spaces and the master bedroom, provided important lake views for all of these rooms in a small house footprint. Second floor spaces took advantage of their higher location for best south facing solar gain orientation. Computer modeling of all the trees on the site, informed best location for the home and solar arrays footprints for maximum solar benefit. | |

| What else should we know? | |

| This project would not come to be if it wasn’t for the values of the client, who wanted to model to the surrounding SW Michigan community that there is a better way to build, that can be better for the planet’s life sustaining biosphere and better for our physical, mental, emotional and spiritual health. The design and building team have tremendous gratitude for this opportunity and experience. | |