“A 73-unit, institutional-style nursing home, built in 1961, was shuttered and the building was in disrepair. Many viewed the dilapidated structure as being prime real estate for razing and redevelopment due to its best feature — a prominent location on one of Milwaukee’s greatest thoroughfares, Prospect Avenue. Where others saw obstacles, one local developer saw opportunity. This developer was Dominion Properties and they knew that there was a unique opportunity to “upcycle” the existing structure and turn it into an attractive and modern apartment building that would be sought-after by residents. To do it right, Dominion Properties knew they had to do it well. And to do it well, Dominion Properties felt it needed to be green. No small feat but they, along with their dedicated team, were up for the challenge.

SAGE ON PROSPECT® – PROJECT DESCRIPTION

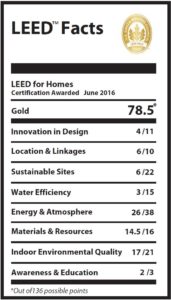

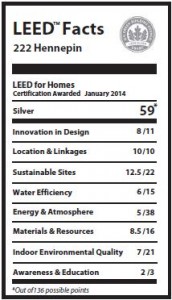

Dominion Properties purchased the property at 1825 North Prospect in 2014 and reconstruction of the building on the site in 2016 included removing one floor of the existing four-story building and then adding two floors to the top to achieve a five-story height. The skeleton of the original structure was kept but the inside was gutted. In doing this, lead and asbestos were removed, windows were replaced, one elevator was moved and another was relocated. The vast majority of the building construction waste was recycled. The reconstruction resulted in thirty- four (34) one and two-bedroom apartments on the five floors along with a modern lobby/entryway and common areas, one level of underground parking and an adjacent surface parking lot. The project team’s commitment to sustainability drove every design and construction decision. This concerted effort resulted in SAGE ON PROSPECT® becoming the second market-rate apartment property in Wisconsin to achieve LEED® Platinum status (the first was Dominion Properties’ Sage on Jackson® new construction project which was built in 2014). Today, the building is fully occupied and both the residents and the owner are reaping the benefits of this highly efficient structure.

EXCELLENCE IN DESIGN & CONSTRUCTION – A COMMITMENT TO SUSTAINABILITY

SAGE ON PROSPECT® was designed to raise the standard for sustainable multi-family housing and green living in the Midwest region. The development offers cutting-edge technologies, innovative building methods and efficient materials. The innovative, “green” design requires less energy, achieves a low carbon footprint, and produces very little waste. SAGE ON PROSPECT offers residents modern amenities for a relaxing home-life, while being located in a thriving urban community.

Differentiating features of SAGE ON PROSPECT® include: LEED

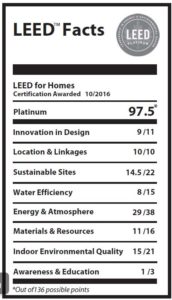

In December 2016, SAGE ON PROSPECT achieved U.S. Green Building Council’s LEED® Platinum Certification. As

one of the SAGE brand developments, SAGE ON PROSPECT joins SAGE ON JACKSON® to become the only two privately funded LEED® Platinum Certified apartment buildings in Wisconsin. SAGE ON PROSPECT earned 92.5 points when only 86 were required for Platinum certification.

Site

SAGE ON PROSPECT is located on Milwaukee’s Eastside at 1825 N. Prospect Ave., near Lake Michigan. As an adaptive reuse project, the development transforms a pre-existing, under-utilized structure into a state-of-the-art luxury building. SAGE ON PROSPECT maintains the area density, offers increased quality and provides a positive addition to the streetscape and environment.

Structure

Innovations at SAGE ON PROSPECT began with the core building structure. The first three levels utilize the pre- existing structure’s superior concrete, steel and masonry. The exterior walls in the upper two levels were newly constructed utilizing panelized, 2×8 wood framing studs which exceed industry minimums. Mineral wool insulation was used throughout. The advantage of using mineral wool is attributed to its superior thermal and acoustical insulation quality, lower energy needs in production, and fewer chemicals added.

Design

Striegel-Agacki Studio, the architect, gave careful design consideration to every detail, with emphasis on the benefits of adaptive reuse (customization, quality and sustainability). The building’s exterior façade incorporates modern textures, colors and architectural details. Typical apartments waste 10-15 percent of each unit’s square footage on circulation space (i.e. hallways, entryways, etc.) The SAGE building’s superior design increases overall usable square footage by reducing the circulation space to about 5 percent. Residents benefit from premium, efficient space, rather than unused, inefficient circulation and common areas. All materials and systems were designed, locally sourced when possible, and selected specifically for the project to achieve maximum reduction in resident energy consumption.

Waste

Adaptive reuse of the pre-existing building allowed for a dramatic reduction in waste compared to an entirely new construction project. SAGE ON PROSPECT is designed to utilize as much of the existing structure as possible. The additional building floors were constructed primarily in an off-site factory, where excess materials are recycled and waste is minimalized. At the building site, Dominion Properties worked closely with the general contractor, Venture Development Group, to implement ambitious waste reduction strategies and recycling protocols so that more than 85 percent of all construction waste was recycled. The building includes a custom waste collection system that allows residents to easily and efficiently dispose of their trash and recyclables, unlike any other building in the state.

Solar PV

In cooperation with FOCUS ON ENERGY® SAGE ON PROSPECT incorporated a 29.45kWhPV photovoltaic system on the roof. This method of generating electrical power converts solar radiation into electricity, which offsets and decreases the building’s overall energy consumption.

HVAC

The building was designed to maximize HVAC efficiency to ensure consistency, comfort and cost savings for residents. Features include twenty-four, 400-foot-deep ground source heat exchange wells that provide an efficient heating and cooling interface for the building. SAGE ON PROSPECT incorporates quiet and efficient heat pumps in each residential apartment. A 95% efficient boiler in the building serves as a back-up heat source and provides on demand heat to the parking area, and used with an innovative cold water tempering tank, provides domestic hot water to the building with minimal carbon emissions.

Lighting

Natural daylight and passive solar opportunities are maximized in the building to benefit residents. All exterior and interior lighting in common areas and individual apartments are 100 percent LED, providing long lasting and efficient light.

Appliances

ENERGY STAR® and other energy efficient products were carefully selected for each apartment. These products save energy without sacrificing features or functionality. All stoves have “AquaLift®” technology, which requires no harsh chemicals or massive amounts of energy (like a self-cleaning oven) to clean. All appliances, with the exception of the microwave ovens, were made in the Midwest.

Rain Water Management Front Awning – Green Roof Main Roof – Blue Roof

Landscaping – Both water-absorbing and drought-tolerant

The small Green Roof holds rain in the soil and allows it to evaporate naturally into the environment diverting approximately 385 gallons per rainfall. Blue Roof technology serves as a retention pond during large rains dropping water into the MMSD system by radio control 12 hours after a rain to help buffer the storm water demand on the waste treatment system of Milwaukee. As much as 7,500 gallons of rainfall is stored at peak.

Vehicle Charging Stations

The building’s garage is equipped with two car charging stations. These charging stations are powered with electricity generated by the solar array and are free of charge to residents who own electric cars.

Elevator

The building’s gearless elevator does not require a machine room and consumes approximately one-third less energy than other elevator types.

Flooring

U.S.-made ceramic tile and domestic zero VOC flooring in a variety of forms is used throughout the building.

Plumbing

Cold water is supplied to all kitchens through copper pipes protecting drinking and cooking water from chemical leaching issues that can result from the use of standard PVC and PEX piping. Domestic hot water is preheated with an innovative ambient heat exchange system that tempers before the traditional process of heating the water with natural gas, therefore further reducing carbon emissions.

Chemical Sensitivity

Every material, from paint and caulk, to floor finishes and carpeting was carefully selected to ensure that the building uses the lowest Volatile Organic Compounds (VOC) and other harmful off-gassing chemicals. The entire building is smoke free. SAGE ON PROSPECT is not only sustainable; it also is healthy to live in.

PROJECT CHALLENGES

Site Constraints

Neighbors on both sides are nationally recognized historic properties, so care had to be taken to avoid extreme disturbances in vibration and noise to protect these notable buildings.

Existing Building Deconstruction

Performing a gut rehab of an existing building versus constructing a completely new structure posed unique challenges. The design and construction teams worked within the confines of the existing building to achieve a new, modern structure that has all of the state-of-the-art features, amenities and building systems that are found today in newly-built apartment projects. Sage on Prospect achieves what new, modern buildings can with the benefit of high quality 1960’s construction practices that are often too costly to implement today.

Achieving LEED Standards

To pursue LEED® certification, the team had to follow a detailed process for material selection. Careful review and consideration was taken to ensure that each submittal met LEED® standards. The team was extremely diligent in their material selection and construction process.

COLLABORATION & A COMMITMENT TO THE COMMUNITY

With the many multifamily developments popping up around Milwaukee, Dominion Properties is encouraging others to considering implementing sustainable construction and living practices. With SAGE ON PROSPECT, they are leading by example and taking the time to educate their residents on the benefits the building offers. They are also eagerly sharing their experiences with other developers, designers and builders in and around the area to inspire and increase sustainable development.

SAGE ON PROSPECT is the second Dominion Properties’ project that proves “green” works. It is an investment in the best interest of the community and our environment now and for years to come.