* correction – This is a new home and not a rehab.

The approach was a LEED certified home that goes beyond most Habitat standards of just LEED silver and Energy Star Version 2. The goal was to get a house to achieve the coveted Energy Star V. 3 certification and Indoor AirPlus certification by achieving higher standards for the HVAC. The biggest hurdle for this house was installing a 95% efficient furnace coupled with an ERV mechanical ventilation system and flexible ducts in order to reduce energy costs and improve air quality throughout the 2-story house. The kitchen is outfitted with low VOC cabinets and a 100 CFM range hood which vents directly outside as opposed to in the attic or re-circulation.

The Indoor airPlus certification contributed largely to the Energy Star V3 Certifcation, as the higher quality HVAC system also covered many of the prerequisites. The biggest hurdle for this home was to find a credentialed HVAC installer who would work with the higher standards required for Indoor airPlus. The water heater and furnace directly vent fumes outside and improve indoor air quality and efficiency of the equipment. The HVAC also has a MERV 10 rated filters and efficiently at 86 CFM, which fully circulates the air in the home approximately every 4 hours. The furnace itself runs on a single speed PSC motor which runs at set intervals and uses the ERV to moderate the temperature. The house also features a Superior Wall Foundation which contributes an R-Value of 5 to NuWool insulation installed on the walls for a total R-Value of 26. To further increase the insulation of the house the rim joists were also insulated and earn an efficient .3 U-factor windows were installed to reduce air leakage.

The home appliances available in this house are Energy Star certified to accompany the Energy Star V3 certification on the house. Outfitted with low formaldehyde pressed wood materials in flooring and cabinets, as well as low VOC paints and finishes on the cabinets and walls. . Plumbing is outfitted using PEX piping as more flexible and reliable alternative to PVC or copper piping.

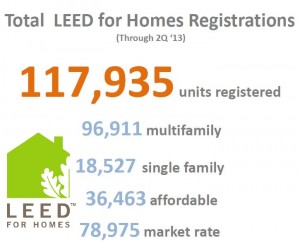

Habitat for Humanity Kent County is committed to 100% LEED Silver Construction and has saved homeowner’s $1,000 a year in utility costs as well as improved their indoor air quality compared to living situations they were previously in.