Design Charrette Grants for LEED for Homes

/2 Comments/in Local, Economics, Tools and Resources/by Brett LittlePre-planning is critically important when designing and constructing a green building. encourages projects to use integrated design, bringing key members of the project team together often in the schematic design phase to discuss the project, set goals and accountability, and solve potential problems up front rather than during construction when its often more costly. Thanks to Green Communities, those who are pursuing LEED for Homes and participate in a Design Charrette, may be eligible for up to a $5,000 grant prior to the charrette.

Eligible Applicants

- Open to 501(c)(3) nonprofits, tribally designated housing entities; and for-profit entities participating through joint ventures with qualified organizations.

- Please note that applications for joint ventures must identify the nonprofit 501(c)(3) organization as the legal entity to receive the grant, if awarded funding.

- The applicant and the development team must demonstrate their qualifications to successfully carry out the proposed development.

- Projects must be subject to firm site control or evidence that site control is imminent. Applicant must identify whether proposed project site is an occupied or unoccupied property.

- Projects must involve new construction of residential units or rehab at an estimated cost of $3,000 or more per unit.

- Projects applying for pre-development Charrette funds must be in the early stages of planning or schematic design phase of development.

Intended Uses of Funds

Funds may be used to cover the cost of conducting a Green Communities Charrette. Expenses include: pre-qualified consultant fee for facilitation; consultant travel costs, not to exceed $1,000; meeting preparation costs, such as creating invitations, meeting and follow-up materials, venue and program support time all not to exceed a combined total of $800. Food is not an allowable expense.

Please note that consultants selected must adhere to the rate policy established by the federal provider of these dollars.

Grant Amounts

Grantees will be required to provide a match of 3:1 in private dollars. Match must be achieved at the beginning of the grant period of performance. Back up documentation must also be submitted to provide confirmation of these sources.

Grant Application and Approval Process

- Submit Charrette Grant application. At application stage, applicants must identify the development goals, intended outcomes, and facilitator information. Please consult your Green Rater and/or LEED APH to discuss outcome of Charrette.

- Receive acknowledgement from Enterprise regarding whether the grant has been approved, denied or approved with conditions. Because funds are limited, Enterprise will reserve the right to negotiate with grant applicants to determine the highest and best use of Green Communities grants in a specific project.

- Execute a Charrette Grant Agreement with Enterprise.

- Charrette Grant applications are reviewed once per month. Applicants will be notified within 4-6 weeks after submission.

More details at http://www.greencommunitiesonline.org/tools/funding/grants/charrette.asp?mkt_tok=3RkMMJWWfF9wsRokv63KZKXonjHpfsX64usqW7Hr08Yy0EZ5VunJEUWy24AIS

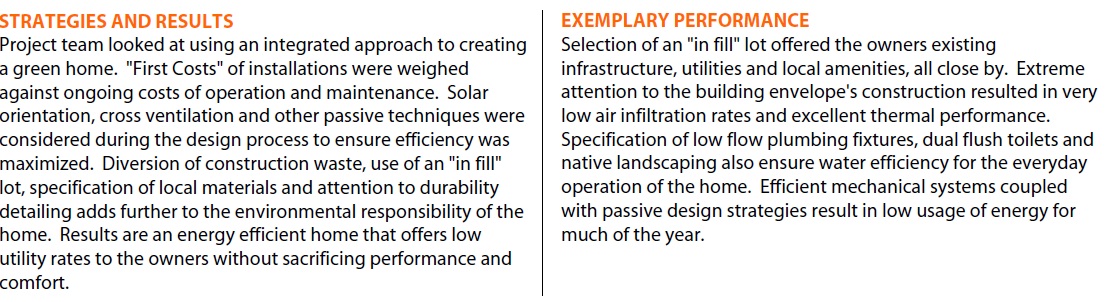

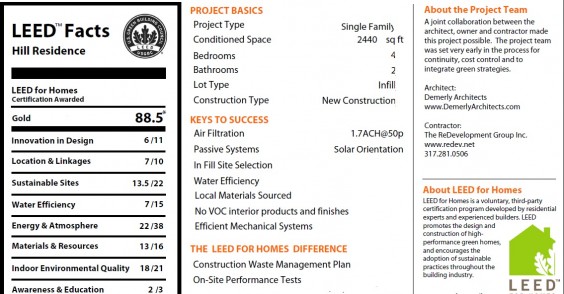

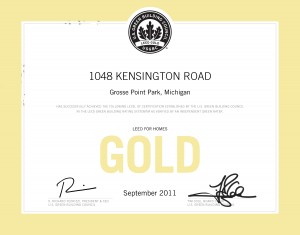

South East Michigan LEED Gold Certified Home

/0 Comments/in LEED Gold, Michigan, Single-Family Projects/by Brett Little‘It’s not that easy being green,” sang Kermit the Frog. While that’s often true when it comes to green building, it is definitely getting easier, say Lynn and Charlie Arnett of Grosse Pointe Park. The Arnetts and their four children, three of whom still live at home, recently moved into one of the Detroit area’s first new LEED (Leadership in Energy and Environmental Design) certified, green-built houses.

The family had been living in a nearby 1950s house and needed more space. They thought seriously about building, but empty lots are hard to find in older, established neighborhoods such as Grosse Pointe, and they weren’t sure they wanted to trade in the frustrations of an older house (asbestos, lead paint, wet basements) for the different but equally challenging issues of newer ones (formaldehyde, medium-density fiberboard).Both have long been interested in environmental issues. Lynn worked in environmental law in Washington, D.C., and Charlie, a teacher, jokes that he recently found a button for the first Earth Day in a box when they moved.

After much thought and plenty of research, they decided to look for a lot where they could build an environmentally conscious new home. Ultimately, that search led them to a 60-by-175-foot corner lot where a condemned 1920s Tudor had been torn down.“We decided we wanted to walk the walk, not just talk the talk,” says Charlie of their decision to build. Doing so had its challenges. Green building has been in the forefront of the news, but mainly in the commercial arena. Green residential building is still fairly uncharted territory, say the Arnetts, especially in Michigan. Still, they were determined to make it happen.

After much thought and plenty of research, they decided to look for a lot where they could build an environmentally conscious new home. Ultimately, that search led them to a 60-by-175-foot corner lot where a condemned 1920s Tudor had been torn down.“We decided we wanted to walk the walk, not just talk the talk,” says Charlie of their decision to build. Doing so had its challenges. Green building has been in the forefront of the news, but mainly in the commercial arena. Green residential building is still fairly uncharted territory, say the Arnetts, especially in Michigan. Still, they were determined to make it happen.

Once they found their lot, they enlisted the help of Joel Peterson of Insignia Homes, a Grand Rapids-based builder whom Lynn had worked with on a former house and who had experience in LEED-certified homes. He led them to Wayne Visbeen, a Grand Rapids-based architect known for designs that successfully blend past and present.

The Arnetts wanted the house to be green but also to blend with the older Tudors and colonials on the block. “It was very important to us that the house fit into the neighborhood,” Charlie says. “We had the architect and builder do a Grosse Pointe field trip before we started.”Priorities included a vintage-style screened porch off the kitchen as well as a large open living space encompassing the kitchen and great room. The house would have six bedrooms and 41/2 baths and the kind of detail — wood trim, glass-knobbed doors, a stucco fireplace, exterior shingles — often found in older homes. Underneath, however, the infrastructure would be green.

LEED-certified houses include things such as geothermal heat, an air recovery system and a long list of environmentally approved materials, including insulation, windows, carpet, even landscaping. “Indoor air quality is very important to us, so we opted for no-VOC paints or finishes, and insulation made of shredded newspapers,” Lynn says. LEED certification is awarded in levels, with points given for each area of compliance. (For more information, visit the U.S. Green Building Council’s website at www.usgbc.org.) The Arnetts are waiting to hear if they have achieved platinum status, the highest level given, and have been investigating the idea of installing cutting-edge solar shingles, a product Dow is pioneering.

Lynn spent hours researching materials and contractors. They struggled to find cabinetry for the kitchen that was formaldehyde-free, ending up with an Indiana company. “You really have to ask a lot of questions,” she says. “It was a big education for us, too.”It took less than a year to build the Craftsman-influenced home. Now that the house is done, they’ve been working with Grosse Pointe Park-based interior designer Fatima Beacham and trying to fill it with “green” furniture — another area that hasn’t quite hit the mainstream yet.

“The problem with a lot of new furniture is that it is built with medium-density fiberboard that contains formaldehyde,” Lynn says. Formaldehyde has been linked to many health ailments. They admit there were times they were tempted to give in and take the easier way. “Staying on track and not letting ourselves be pressured to compromise was challenging,” Charlie says.“There were times I was tempted to cave, but Lynn kept me going.”

“The problem with a lot of new furniture is that it is built with medium-density fiberboard that contains formaldehyde,” Lynn says. Formaldehyde has been linked to many health ailments. They admit there were times they were tempted to give in and take the easier way. “Staying on track and not letting ourselves be pressured to compromise was challenging,” Charlie says.“There were times I was tempted to cave, but Lynn kept me going.”

While building green is a bit more expensive than standard construction, tax credits and governmental rebates help, and prices should decrease as demand goes up, the Arnetts say. For their family, going green has been the right choice. “Once you get started, you want to do it 100 percent,” Lynn says.“When it comes to residential construction, LEED is still in its beginning stages. We’d love to be a resource for other homeowners. Hopefully our experience will make it easier for the next folks who want to do this. Even choosing a low or no-VOC paint for your next project is a good start.

View complete project profile here

”The Arnetts recommend the following contractors and manufacturers:

Architect: Wayne Visbeen (www.visbeen.biz)

Builder: Joel Peterson, Insignia Homes (www.insigniahomes.us)

Kitchen cabinets: Mutschler Kitchens, Karen Rozanski (www.mutschlerkitchens.com)

Flooring: Chelsea Plank Flooring (www.plankflooring.com)

Carpeting: Mohawk SmartStrand (www.mohawkflooring.com/smartstrand)

Custom cabinetry: Dutch Made Cabinetry (www.dutchmade.com)

Paint: Sherwin-Williams no-VOC “Harmony” paint (www.sherwinwilliams.com)

Toilets: TOTO Dual Flush Toilets (www.totousa.com)

Landscaping: James Leamon Landscape Design, (313) 407-8137

Khristi Zimmeth is a Metro Detroit freelance writer and Homestyle’s Trash or Treasure? columnist.

From The Detroit News: http://detnews.com/article/20110218/LIFESTYLE01/102180306/Grosse-Pointers-build-certified-earth-friendly-home#ixzz1EOaEKWMz

“River Escape” Home Tour – Pending LEED Platinum

/0 Comments/in Education and Events, Michigan/by Brett LittleOn 11.11.11 come see an affordable home that was built to be 88% more energy efficient than and standard new code built home. This home is a Zero-Energy home that is projected to be a LEED for Homes “Platinum” project. The home is also a finalist for Green Builder Magazines 2011 Home of the Years.

Pending AIA Approval

Please RSVP with us at.

616.957.LEED (5333) or at

ehughes@imagedesignarch.com

“River Escape” Home Tour

November 11th at 10:00 am and 1:00 pm

7121 River Escape

Stanwood, Mi.

Sponsored by

Eric Hughes of Image Design, LLC

Adam Eerdmans of Turtle Walls

Tim & Dawn Gruss Home Owners

The “River Escape Project”

Resting in Western Michigan’s vacation wonderland, this home is located near the Muskegon River in Stanwood, Michigan with river access, thus the project name. This home is a site specific, 1,267 square foot Passive Solar Contemporary Style home built with BuildBlock ICF (Insulated Concrete Forms) from frost protected shallow foundation to the SIP roof. The exterior elevations of the home were designed with deeper roof overhangs, determined by using solar calculations, to both maximize and minimize the sun exposure based on the time of year. The exterior used two of our favorite products James Hardie FiberCement Siding and MiraTec trim. The interior of the home has stained concrete floor on the main level which makes for great thermal mass. The home was also designed with lifetime design principles and has zero step entries.

Part of the passive solar design is to have very few windows on the non-south sides of the home, to keep heat from escaping through them. That is why this homes attention to detail is spent on the Southside of the home, where most of the homes windows face south. The windows in this home are made by North Star (Canadian made) which uses a transparent low-E film between the panes of glass with a foam spacer to get a triple pane effect without the weight or waste of extra glass. The window U-value is .24 with a much higher Solar Heat Gain Coefficient (SHGC) on the South windows. In the winter, the sun will warm the living space during the day and shine on the concrete floors which will store some of the heat gained, for gradual release. The roof overhang will shade the house from excessive solar heat gain in the summer, and west-facing glass is minimized to reduce cooling needs in the summer. ICF construction was perfect for this project because with ICF’s there are no concerns with noise and wind. It is wonderful to quietly contemplate the winter storms swirling through the open fields and feel pleasantly comfortable. The “River Escape” project is a Zero Energy Home (ZEH) thanks to the Passive Solar Design, 4.1 kW of Photovoltaic, Solar Hot Water and a 98% efficient boiler for the radiant floor heat and hot water backup. The home is also pre-wired for future installation of a Wind Generator. This home only uses about 600 kWh of electricity per month and has been generating a minimum of 20 kWh of electricity per day and net-metering backwards every day since the home was completed in June. The home was built for $142.00 per square foot (before the 30% rebates from the Solar Hot Water, and Photovoltaic systems) making it more affordable for the general public. Besides the LEED for Homes “Platinum” certification (this project scored 32.5 points above “Platinum”) this home received 5+ Energy Star certification and a HERs score of 12. This is the lowest score ever tested in the State of Michigan making it the most energy efficient house in Michigan. This home is 88% more efficient than a conventional code built home. The home is also ZeroStep “Silver” Certified (Lifetime Design or Barrier Free) from Disability Advocates of Kent County Michigan. In addition this homes toilets, faucets and shower heads are super low-flow for superior water efficiency. The home also has low-VOC paints, adhesives and finishes and uses recycled content for the flooring, foundation, exterior walls, trim and siding. Every possible piece of unused material used in construction was recycled.

Key Sustainable/Green Features

• Rain Permeable Gravel Driveway.

• Lifetime Design (Barrier Free)

• Zero step entries.

• Energy Star North Star Triple Pane Windows.

• Energy Star LED & CFL lighting.

• Energy Star Ceiling Fans.

• Energy Star Appliances by Frigidaire.

• SIP Panel Roof

• Frost Protected Shallow Foundation (with R-20 Dow Insulation beneath it.)

• BuildBlock ICF Construction (with 40% Fly-Ash)

• Advanced Framing (Studs @ 24” o.c.)

• James Hardie FiberCement siding (with recycled content)

• MiraTec Trim (formaldehyde free, SCS Certified)

• Central Vacuum System (Greatly reduces in-door air pollutants)

• Concrete Floors through-out main floor. (Colored in the concrete mix)

• FSC certified Bamboo Flooring on second story.

• FSC certified stud interior walls.

• No-VOC Paints and primers.

• Low-VOC caulks and sealants.

• Amish Built Kitchen Cabinets from wood within 5 miles from the project site.

• Dual-Flush toilet by American Standard.

• Low flow shower heads and faucets.

• Pex Plumbing.

• Radon Venting.

• Radiant Heat Through-out Home.

• Life breath HRV (heat recovery ventilator)

• Passive Solar Design.

• Solar Hot Water. (30% Tax Rebate)

• 4.1kW of Photovoltaic (30% Tax Rebate)

• Pellet Stove (Back up Heat System)

• Pre-wired for a future Wind Generator.

• Pre-wired for future battery backup.

By Eric A. Hughes of Image Design, LLC

10 Common Failures in LEED for Homes Projects

/0 Comments/in Local, LEED Credits/by Brett LittleAvoid these errors to make sure you ace your final inspection but also these are just great all around tips for Green Building. LEED or not.

1. Manual J Equipment Sizing Calculations. Builders use Manual J calculations to determine the proper size of heating and cooling equipment based on a home’s size and tightness. Using the calculation properly is important in ensuring the equipment works efficiently in high-performance homes. Foss sees several common errors, however. One issue is when the calculation doesn’t reflect the home actually being built—the contractor just uses the defaults, or forgets to update the calculation even though the building has changed. Sometimes contractors will do the calculation retroactively, after the equipment is installed, or make one calculation that they use and another one “for the LEED people.”

“You lose the benefit if you’re just doing it for the paperwork,” Foss said. If you have questions, simply ask your rater—they’ve been through the LEED process before. “It’s better to ask questions before ordering the HVAC equipment,” she said.

Some common calculation errors to avoid: Make sure you have the right city listed, that the home’s infiltration is rated as “tight,” and that the insulation values of the walls and windows are accurate. And don’t try to mislead your green rater—it’ll just add time and frustration to the certification process.

2. Duct Leakage. LEED for Homes requires certified projects to reduce duct leakage to 6%, so it’s important to pay attention to detail. Look for duct boots that aren’t sealed to the drywall and places where the top of the duct is not sealed. Make sure installers seal connections with tape or mastic adhesive in addition to using a mechanical fastener—a zip tie won’t seal.

To avoid running into any problems, Foss suggested builders work with HVAC installers to make sure they know both how to properly install the equipment and how the testing will be performed. Seal the mechanical unit before it’s set in place, and test the system before close-in, especially if it’s the installer’s first time working on a LEED project.

3. Air Flow. Proper air flow around the home is important for even and efficient distribution of conditioned air, so these LEED credits help builders ensure their homes are comfortable throughout. Foss said one common problem is poor duct installation—kinked or sagging ducts, long runs, or too many bends. Another is missing air flow return pathways in the bedrooms.

Foss suggested some fixes to avoid any issues during certification. First, use the duct design. Ducts are a commonly changed site-built item, but following a plan can avoid errors. Second, discuss what type of start-up the HVAC contractor will perform and how they’ll be on the hook for the design they gave you. Third, install dedicated return jumper ducts or transfer grilles in rooms with a door. Using the Energy Star Version 3 HVAC installer checklist and companion guidebook can help ensure installation is completed properly.

4. Air Filters. Be ready for inspection by walking the site and looking for any of the original blue air filters that weren’t replaced with higher-MERV versions. Foss said green raters often see this issue as an indication the builder may have missed other details. “If the builder isn’t clear on it, how will the homeowner know?” she asked.

5. Bath and Kitchen Fan Exhaust. Foss said a common problem is that homes don’t meet the exhaust fan testing requirements of 50 CFM for bath fans and 100 CFM for kitchen fans. The most common reason is that the builder buys a bath fan with too low of a nominal rating. You can’t just buy a 50-CFM fan to meet the requirements, she said, because the rating doesn’t take into account the ducting or other obstacles. You’ll often need an 80- or 100-CFM bath fan to meet the testing requirements. A common issue in the kitchen is improper installation of the microwave, preventing the dampers from opening. Make sure different trades are communicating to double check that the fans work after installation.

To diagnose potential problems, turn on the fans and listen. If it sounds wrong, Foss said, something is going on. Try the toilet paper test—the exhaust fan’s air flow should be able to hold up a square of it. And finally, double-check to make sure dampers aren’t painted shut at the exterior.

6. Ventilation and Exhaust Controls. LEED requires mechanical ventilation, and the homeowner must know how to use it. Some buyers have an expectation that today’s green homes can be completely run from a smart phone, so ask them about their expectations. Think about how they’ll be using the system.

The right controls will be contingent on the ventilation strategy. Is it exhaust, supply, or balanced? Continuous or intermittent? Are other systems involved, such as the bath fan or air handler? For exhaust-only systems, a delay timer is helpful in the bathroom. And even if the bath fan is running continuously to meet ASHRAE requirements, you’ll probably need a boost switch to kick it into a higher mode after showers. If you’re using central ductwork with an energy recovery ventilator or heat recovery ventilator, make sure the ventilator interlocks with the air handler.

7. Air Sealing. Foss said the common issue she sees with air sealing is penetrations through the air barrier. “Make sure you think about what is the air barrier, and relay that to the trades so they know when they make penetrations,” she said. Decide who is responsible for penetrations. Will the plumber seal any holes he makes? Are you hiring an air sealing company? Also remember that spray foam is not a total air sealing package. You still need to seal between studs, for example. In multifamily projects, make sure there is no air movement between units, as well as between units and the hallway. Don’t assume fire stopping is the perfect air barrier.

To avoid issues, include the air sealing details in your plans. Assign responsibility and train all crews. Do a mock-up unit that the green rater can pre-inspect—this is often used as a training opportunity for the crews. Finally, consider purchasing a blower door test for yourself, and start testing.

8. Insulation. There are a number of easy ways for builders to go wrong with these LEED credits: missed insulation in tricky areas, differing R-values, batts compressed at the corners, and missed bays that are hidden by other batts are all common problems.

With spray foam insulation, look for even installation with no valleys in the middle. Measure the depth of the insulation while the truck is on site so subs don’t have to come back to correct any problems. Leave enough time before hanging the drywall to make corrections.

9. Project Team Communication. A common problem builders face, Foss said, is not updating project team members on any changes. On LEED homes, in particular, you need bottom-up understanding of what’s happening with the project. A change in one part of the house might affect the mechanical equipment selection, for example.

Write the LEED requirements into your specifications and follow them, Foss suggested. Assign responsibilities down to the last half point. Also decide upfront who will pay for fixes or re-inspections to avoid being left on the hook for the cost of a contractor’s error.

10. Documents and Submittals. Some LEED points require documents and records, such as product details and waste. Include documentation requirements in subcontractors’ scope of work or contract. Tying those requirements to payment can be an effective way to ensure the requirements are met, Foss said.

Presenting at an educational session at the recent Greenbuild Conference, Foss, managing partner of Washington, D.C.-based green building consulting company Everyday Green, recounted the inspiration for her presentation.

“The developer was upset because she had failed some of the items,” Foss said. “She said, ‘I wish I had known to look for these things beforehand.’ ”

To help other green building professionals avoid making that developer’s missteps—as well as the mistakes she made while rehabbing her own home to LEED standards—Foss listed the 10 most common issues she’s found during her LEED inspections:

Jeffrey Lee is Managing Editor of EcoHome.

Announces Partnership with 1% for the Planet

/0 Comments/in Local/by Brett Little is a new nonprofit partner of 1% for the Planet, an alliance of over 1,380 member companies in 43 countries that give one percent of revenues to environmental causes.

is now eligible to receive donations from 1% member companies, placing them among a diverse, global network of environmental organizations. 1% member businesses fuel this non-profit network through their annual contributions, which totaled over $22 million in 2010. Partnership with 1% greatly expands the potential pool of funding to which can look to for support.

Newly approved contributes to a healthier planet by educating builders, architects, developers, contractors and the general public on Affordable, Healthy, Efficient and Durable green building practices.

Over 2,300 non-profits worldwide are included in the 1% network, and over $70 million has been funneled to its nonprofit partners to date. “The intent of 1% for the Planet is to help fund these diverse environmental organizations so that collectively they can be a more powerful force in solving the world’s problems,” Yvon Chouinard, founder of 1% for the Planet.

“ is a small but formidable organization made up of a larger network of leaders in the field of green building education and consulting services. is developing a web based, user friendly, transparent, and no cost living certification on green building and living practices that homeowners and businesses will be able to utilize to make smart and practical decisions in their lifestyle’s and operation’s” – Brett Little, Administrative Director

About 1% for the Planet

Started in 2002 by Yvon Chouinard, founder and owner of Patagonia, and Craig Mathews, owner of Blue Ribbon Flies, 1% for the Planet is a growing global movement of over 1,350 member companies in 43 countries that donate one percent of their sales to environmental organizations worldwide. Each day, more than one new business joins the 1% for the Planet movement. As a network, the 1% community has become a frontrunner in funding the work of environmental groups around the world. To learn more about 1% go to: www.onepercentfortheplanet.org

About

The Alliance for Environmental Sustainable is 501c3 non-profit that is a resource dedicated to helping people understand the options available for designing, building and occupying structures that offer environmentally friendly alternatives, energy efficient products and improved indoor air quality. Due to the need and the emerging interest of green practices, LEED, and sustainability has grown and now serves communities throughout the United States. serves the US and international

Numbers, Know-how and navigating LEED in affordable housing

/0 Comments/in Local, Affordable Housing, Common Myths, Economics, Education and Events, Illinois, Indiana, Michigan, Minnesota, Ohio, Wisconsin/by Brett LittleJoin USGBC for a free 3-part webinar series exploring the green affordable housing movement.

– Examine market examples to discover factors driving green affordable housing, as well strategies for success and the benefits to going green when tackling affordable housing projects.

– Explore the synergies between keeping design and construction costs down and building in a responsible, sustainable fashion.

– Identify tools and strategies to finance retrofits of existing multifamily developments while taking an in-depth look at affordable housing and LEED.

All sessions will be held from 1:00 to 2:30 PM EDT.

|

Oct. 20, 2011 |

Driving Smart Decisions in Green Affordable Housing |

|

Nov. 3, 2011 |

Financing Green Multifamily Retrofits |

|

Dec. 8, 2011 |

LEED Certified Affordable Housing: It gets better every time |

Register today »

Each session in this series will be registered for 1.5 hours of continuing education with AIA/CES SD/HSW, and GBCI CMP hours for LEED professionals.

Congratulations to two new Green Raters Serving Michigan & Ohio

/0 Comments/in Michigan, Ohio/by Brett LittleAlex Babycz & Pam Pierce are two new Green Raters joining the Green Home Institute and serving their regions on LEED for Homes verification and consulting. Contact them today with questions on new projects.

Alex Babycz

LEED AP BD+C

Natural Solutions Construction Co., LLC

3934 Tubbs Rd.

Ann Arbor, Mi. 48103

Phone.: 734-660-0128

E-mail: greenrater2@gmail.com

Area Served: South East Michigan / Area Codes: 734, 313, 248, 947, 586, 810

Pam Pierce

Learn About Green, LLC

Gates Mills, Ohio

PH: 440-341-0955

Email: pam@learnaboutgreen.com

Area Covered: North & Mid Ohio

Other Services Provided: BPI, HERS, Green Communities & LEED APH

New Appraisal Form details Green and Solar Features

/0 Comments/in Economics, Illinois, Indiana, Michigan, Minnesota, Ohio, Single-Family Projects, Tools and Resources, Wisconsin/by Brett LittleThe Appraisal Institute, the nation’s largest professional association of real estate appraisers, has made it easier to identify attributes of green homes. Last week, they released a form intended to help analyze values of energy-efficient home features. It is the first of its kind intended for appraisers’ use.

The new form is intended to be used as an optional addendum to Fannie Mae Form 1004, the appraisal industry’s most widely used form for mortgage lending purposes. Used by Fannie Mae, Freddie Mac and the Federal Housing Administration, Form 1004 is completed by appraisers to uphold safe and sound lending. Currently, the contributory value of a home’s green features is rarely part of the equation.

“This addendum is another example of how the Appraisal Institute is at the forefront of real estate valuation,” said Appraisal Institute President Joseph C. Magdziarz, MAI, SRA. “It will help the industry standardize the way residential energy-efficient features are analyzed and reported.”

The Appraisal Institute’s addendum allows appraisers to identify and describe a home’s green features, from solar panels to energy-saving appliances. Form 1004 devotes limited attention to energy efficient features, so green data usually doesn’t appear in the appraisal report, or it is included in a lengthy narrative that often is ignored.

Magdziarz pointed out that the Appraisal Institute’s form also will make it easier for appraisers to determine whether recent home sales should be used as comparable sales. Sales that are truly comparable are key components in determining a property’s value.

While the addendum won’t guarantee that an appraiser will raise a property’s value by tens of thousands of dollars for energy-efficient upgrades, it should guarantee at a minimum that energy improvements will be taken into account based on value adjustments consistent with local market conditions. More importantly, appraisers using the new addendum should be better equipped to identify accurate, area-specific comparable sales.

One of the interesting aspects of the form is the emphasis given to describing renewable energy systems such as solar photovoltaic. The form has an area where data collected by the appraiser could easily be used to calculate the net present value (NPV) of the energy savings from a solar energy system. Other aspects include identification for third-party certifications such as LEED for homes.

Research – LEED Homes Cost of Ownership

It’s worth noting that this is an optional addendum to a traditional 1004 appraisal form. Hopefully the lending community will embrace this and builders, architects, lenders, appraisers, and other real estate professionals all find value in encouraging the use of this form for green homes.

Download the Appraisal Institute’s two-page green addendum, which is also listed as part of the Green Real Estate Toolkit.

Learn more about the Green Addendum and how it will be used at a free event on Oct 24, 2012 in Oak Brook, IL.

And don’t forget to review the Green Home Institute research report showing the total cost of ownership savings found from building healthy, efficient green homes.

Menu

GreenHome Institute

GreenHome Institute

ATTN José Reyna

1451 Lake Drive SE, #6484

Grand Rapids, MI 49516

Tel: (616) 458-6733

Email: info@greenhomeinstitute.org

About Us

Recent Posts

- April 2024 GreenHome and Sustainability Jobs Round-Up.

- Protected: Public comment on Inflation Reduction Act Home Rebates opening in MI and beyond

- Shawn Neinhouse completed Certified GreenHome Professional Training

- Please take this MSU Student’s Mass Timber Survey

- Clean Energy Credit Union Clean Energy For All Reduces Barriers