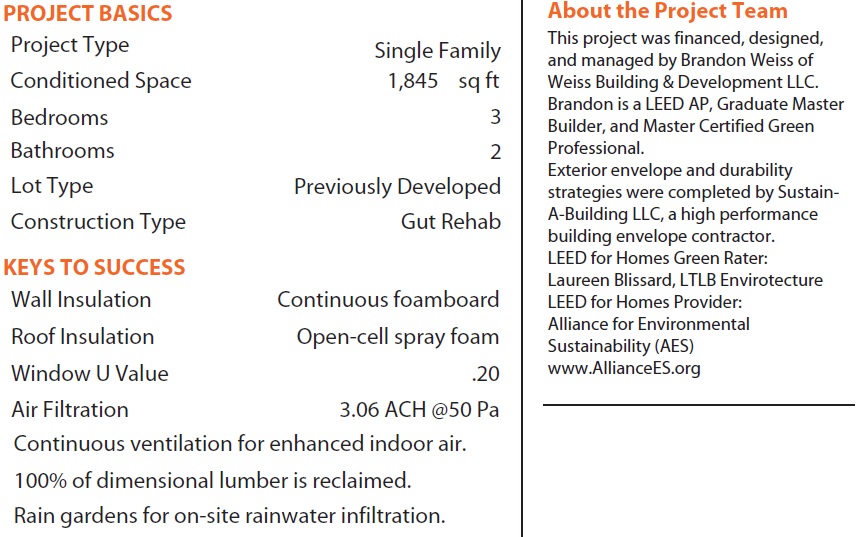

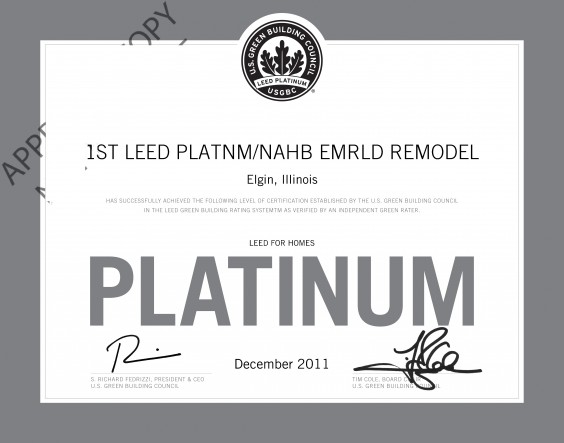

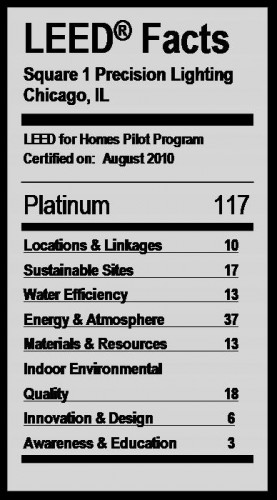

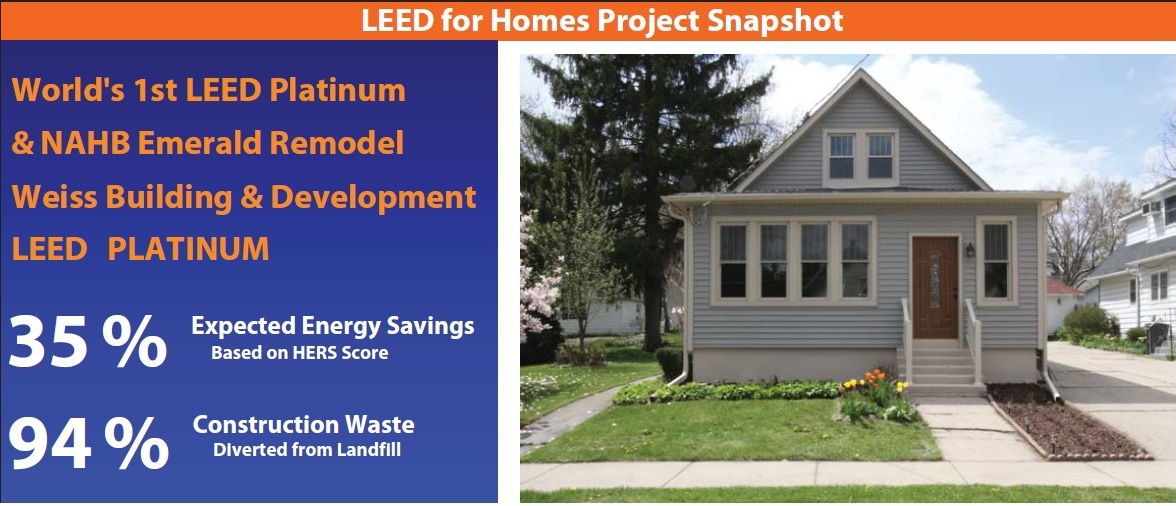

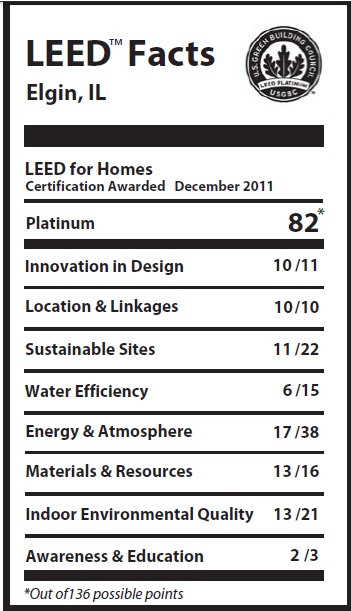

The goal of this home was to take a foreclosed home in disrepair and turn it into a high performance, healthy, utility efficient, environmentally responsible, and very durable home. Durability planning was used in conjunction with building science flashings and maintenance free exterior materials with lifetime warranties. The energy efficiency was improved by almost 300% on this home with air sealing, wall cavity insulation, exterior insulation, and windows with a .20 u factor. All materials used were non- toxic, low VOC, and had no added urea formaldehyde.

This home received two exemplary performance credits for MR 2.2. This was due to many extra points in that category for a high level of reclaimed materials usage, the use of locally produced products, and the use of low emitting products. All lumber used for framing in this house was reclaimed lumber. This remodel was done as an investment property, rehabbed and turned over and placed on the market for sale. The sales prices was comparable to other rehabbed homes in the local market. Construction costs on this project were impressively low at $55.00 per square foot.

This project was featured in the Chicago Tribune, Exerpt below.

Few homebuilding materials can’t be reused or recycled, said Brandon Weiss, president and owner of Elgin-based Weiss Building, who recently salvaged 99 percent of the material from a four-bedroom, two-bath home he rehabbed in Elgin.

“Everything that could get a second life, I donated,” said Weiss, who has become somewhat of an expert at reusing construction leftovers, filling in old crawl spaces with leftover bricks and using stones as landscaping accents.

While the tax benefits from donating construction materials are nice, it’s “our children’s future” that clinched the case for him, he said: “Our landfills are full. You can try to close that loop and reuse things.”

Homeowners who are planning a construction project should know that many waste companies can recycle discarded materials from trash containers and will prepare a report on the percentage of materials they are able to divert from landfills, said Jason LaFleur, regional director of the nonprofit Green Home Institute.

“If they can’t provide the service, you might want to think about going with someone else,” he said.