Starting with an eco-conscious dream for a truly green home transformed owner Michael Yannell’s Chicago residence into a $1.6 million, two-story 2,675-square-foot, four bedroom and two-bath Net-Zero-Energy masterpiece, producing 40 percent more energy than it consumes.

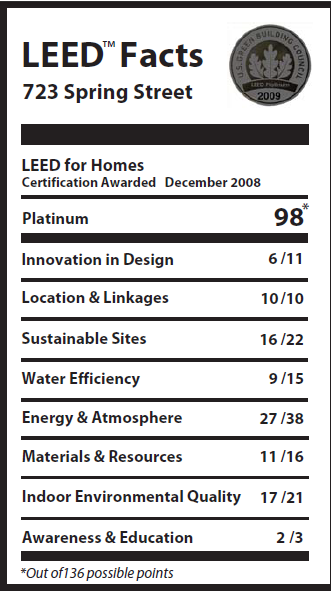

Completed in 2009, it is not only Chicago’s first LEED Platinum-certified home, but it has scored higher than any other LEED-certified project in history. Architect Farr Associates, builder Goldberg General Contracting Inc. and engineering MEP firm dbHMS created this urban infill project to utilize aspects of alternative energies through passive solar, solar grid technology, a greywater system and closed looped geothermal heating and cooling components. According to owner Michael Yannell, the main goal of this project was to create a more energy- and water-efficient, environmentally conscious place to live and to set an example by building a home as sustainable as possible. Incidentally, the green materials generally were no more expensive than conventional alternatives.

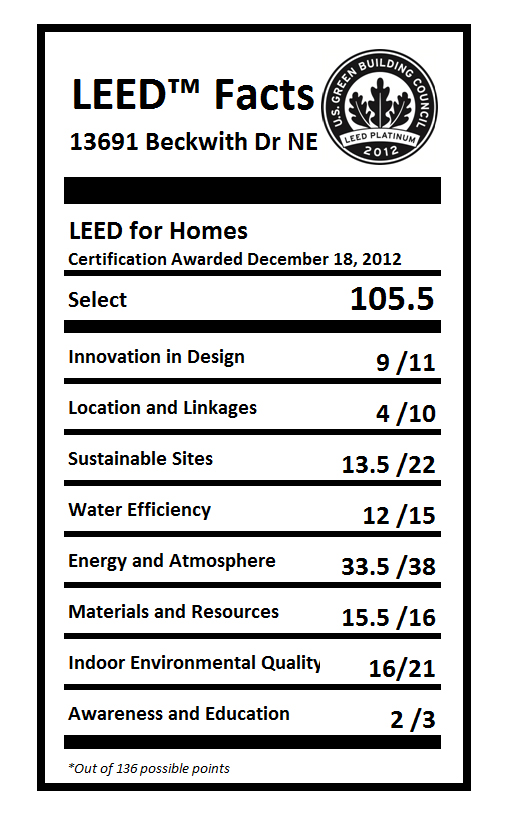

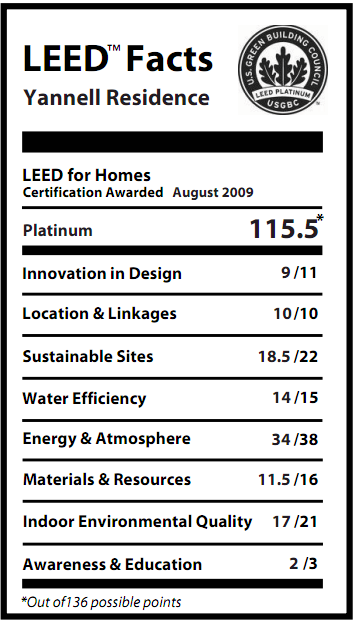

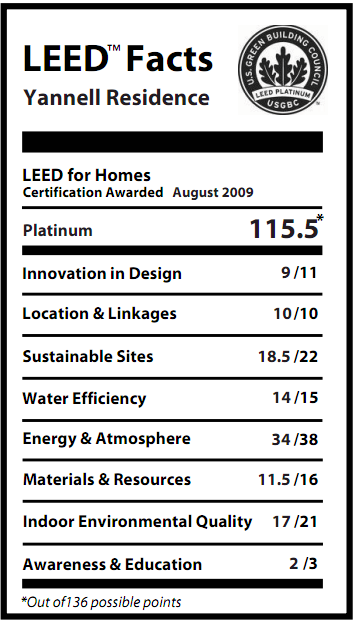

This Net-Zero-Energy residence was built using the U.S. Green Building Council’s (USGBC) LEED for Homes Pilot Program regulations. In order to earn the coveted LEED Platinum-certification, a project must meet the 100-point requirement, in which the Yannell residence scored 115.5. According to Net-Zero statistics, the Yannell residence generates 18,000 kWh/yr and uses only 12, 689 kWh/yr, earning the Yannell property an approximate $52,000 in tax credits in 2008-2009.

According to Jonathon Boyer, principal and director of architecture for Farr Associates, the permit and design processes were a challenge from the beginning, but thanks to help from a hand-picked team, deadlines were met and the project was a success.

“We put together a team of engineers, contractors, and a landscape architect, and the entire project was a team effort,” Boyer said. “Building Net-Zero-Energy is very difficult, and it requires cooperation between all components and consultants. We believe we’ve broken the sound barrier with this house, especially in the Chicago area.”

This being the first LEED-certified home came with obstacles along the way. According to Boyer, by creating new systems such as the greywater system, which recycles water used from the washing machine for the toilets, it was tricky trying to solidify the permit process. It has opened up new options for Chicago to consider when building more sustainable homes.

“It was a learning process, the city of Chicago was open to it. We didn’t have any hard and clear standards in the city for permitting this kind of system,” Boyer explained. “As a result of this house, the city of Chicago Committee of Standards and Tests is adopting a new state / city code for rainwater / greywater reuse. “We were pioneers and induced the city to think about changing permits to use more sustainable elements into the residential market,” Boyer said.

Other than utilizing alternative energies, the Yannell residence’s modern design integrated into the traditional neighborhood fuses form with function in a dense infill space. The home was built on a recycled lot where the previous building could not be salvaged. Boyer explained that typically energy-efficient homes are bland and lack style, but in this case, the owner and the building team wanted something well-designed and unique.”He [owner, Michael Yannell] wanted something aesthetically compelling and functional,” Boyer said.

The floor plan is designed as a dual-wing connected by a foyer, which acts as an entry and passageway, both equipped with south-facing windows to utilize natural light and garden views. The positioning of the wings help compete with the Midwestern climate year-round. With temperatures ranging from the high 90s in the summer to blistering zero-below winters, it was crucial to find the most sustainable design possible. Each wing has a uniquely shaped multi-functional V-shaped green-roof designed for stormwater management and for concealing the 48 photovoltaic grids on the home. “The butterfly pattern roofs are designed to screen the solar panels from view, while providing an ideal angle for the panels to harness the sun’s energy,” Boyer said.

Although the Yannell residence has received the highest LEED score, the materials it took to achieve the title are not unattainable for other eco-conscience projects. According to Boyer, “LEED for Homes is less than $3,000 for certification.” In this case, it assisted in the construction process by acting as a detailed guide when installing aspects such as air quality, water systems and when planning the positioning. Although there is no set specific standard definition for a Net-Zero- Energy home, Boyer said that there are other homes out there that claims to be Net-Zer-Energy, but many have only lowered their energy consumption. Only the Yannell property has the data to back it up. According to Principal of MEP firm dbHMS, Sachin Anand, “It’s [the Yannell residence] the future of housing and power generation where each home is a greenhouse emission-free power plant.”

View LEED for Homes Project Profile

Photography By Christopher Barrett. Evan Lancaster is an editorial assistant at Green Homebuilder magazine. He may be contacted at elancaster@penpubinc.com.

Built for the Future. The Yannell residence in Ravenswood, Ill., a traditional neighborhood outside of Chicago, breaks barriers of traditional homebuilding by perfecting green practices. From http://www.greenhomebuildermag.com/fall42.php