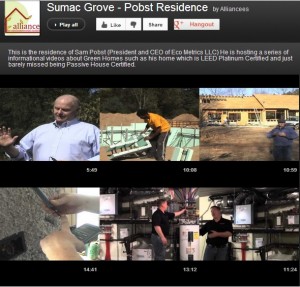

Finally it is here – after 2 years of filming and a big thanks to four Grand Valley State University Interns, 2 hours of video detailed in over 10 sections on the how and why of LEED for Homes and Passive House construction specifically to Sam Pobst’s home.

Sam and some of the other high performance building professionals take us through many aspects: site selection/design, insulation, heating and cooling, passive building, water efficiency and renewable energy.

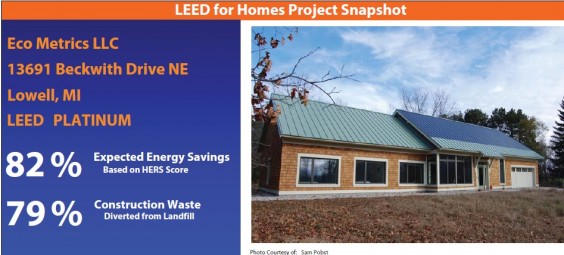

What makes it Green? For starters, Michael Holcomb – President/CEO and owner of Home Inspector General has called this “the tightest home I have ever tested.” It comes in at 0.44 ACH @50PA (for all you energy geeks). Michael has test thousands of homes and buildings in the Midwest in his 20 years of experience, so that is saying something.

Next, this project almost achieved Passive House standards! Sam worked with an experienced PHIUS rater “John Semmelhack” to use the advanced modeling software to design his house. The house tested below the air change requirements of Passive House but only made 7.20 KBTu’s as opposed to the required 4.75 (energy geek talk). Sam’s reasoning: “The primary driver of that cost was the building geometry. Since a primary objective was to build a barrier free home, we designed it all to be on one level. This meant that the ratio of exterior wall and roof area to the floor area was not optimal for thermal design (of Passive House). It was more important to us to have the barrier free design than to meet the PH requirements, though we came very close. The only changes we made from the original PH design was to reduce the thickness of the perimeter walls from 22” to 19”, and specify a window that was not quite as high performing as the one that would attain the PH rating.” Sam told me that there was 99 year back on the window required to meet the standard (at that time).

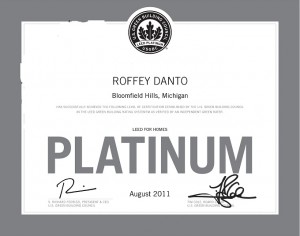

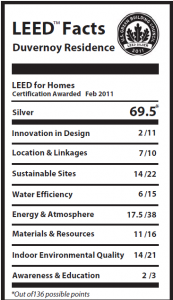

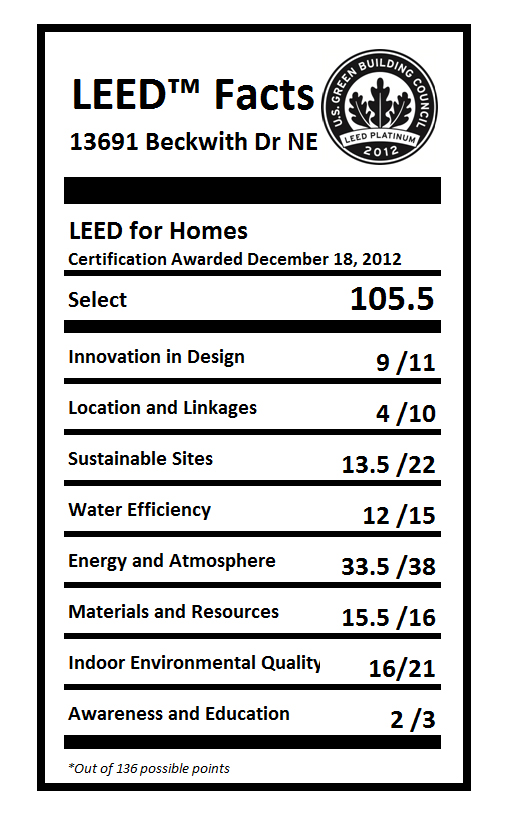

Last, LEED for Homes Platinum Certification has been achieved. This requires 3rd party onsite verification that proves through actual testing that the home is green.

This must have cost millions right?

“We spent $167.00/Square Foot, but if you add in O+P, design fees, and my sweat equity, I estimate about a $200/Square Foot cost to construct.” – Sam Pobst

• Gross Square Feet 2010

• Basement Square Feet 851

• Conditioned Square Feet 2547

• Garage / Workshop 621

• $167/Square Foot Hard Cost

• $200/ Square Foot Buildable Cost

- + Overhead and Profit

- + Design Fees

- + Sweat Equity

Objectives

- Gain a basic understanding of the Passive House (PH) design standards for homes and products or technologies are needed to achieve it.

- Discriminate between LEED, Net Zero, universal design and Passive House objectives and how they interact.

- Learn about behind the wall thermal envelope strategies for a super tight and insulated home.

- Identify costs, ROI and payback on high performance home LEED projects

Continuing Education

- 2 GBCI – LEED Specific

- 2 AIA – LU|HSW

- 2 MI Contractor (Code & Green)

- 2 MI Architect

- If you need continuing education units for a license in another state, this course may apply. Please consult your state’s requirements.

Project utility data update and ROI data

These webinars are free to review. If you are interested in continuing education credits, you must follow the following steps:

1. Read the info above, watch the webinars for FREE and check out the Project Profile.

2. Take the 13 question quiz and score at least 80% to be approved. Please also post a comment below and help add to the conversation.

3. Pay the fee below if this is not taken as part of our GreenHome Associates series to get your certificate and CEUs. You must be a member to pay the reduced member fee.

| Webinar Pricing |

Further Resources

Read back on Sam’s progress documented on his Blog and stay informed as he monitors the home’s energy use, durability, comfort, indoor air quality and water use. http://sumacgrove.blogspot.com/2013/01/certified.html

- Recorded 1 Hour Webinar on the entire project – 1 AIA/GBCI

- 2 Hour GBCI approved Film Series documenting the project from start to post occupancy informed can be seen here for free