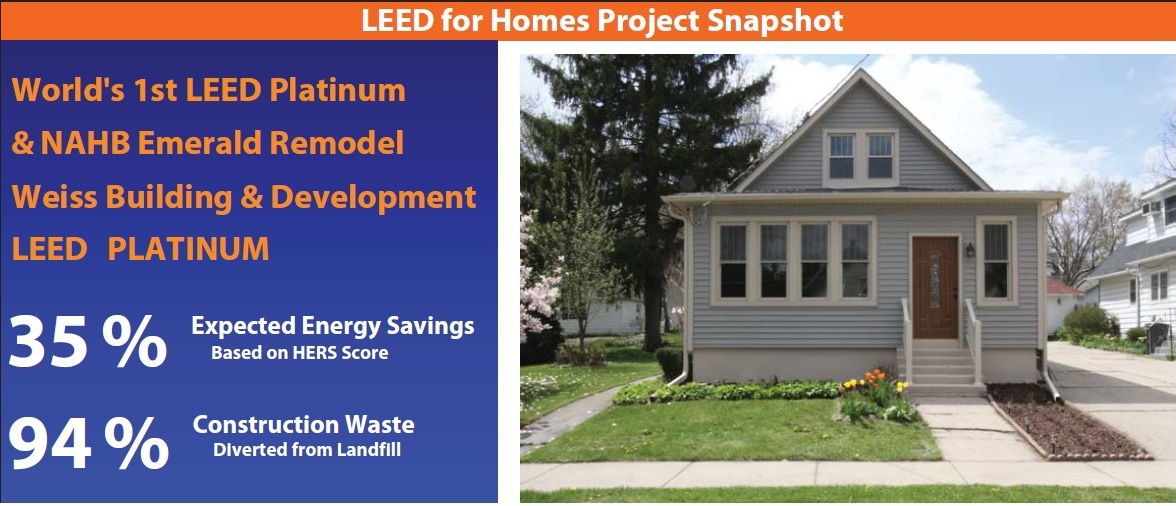

Designed by Young & Young Architects, the contemporary “green” house is constructed of stone, cement plaster, copper, and glass. A bridge connects two sections of the home. The landscaping consists of indigenous, drought-resistant plants and grasses. all the materials used to build an ultra-green home in Bloomfield Township came from within a 500-mile radius, to meet LEED (Leadership in Energy and Environmental Design) requirements. But the idea for the house took root thousands of miles away.

“We travel to South America a lot, and when we’d fly over the jungle, we’d notice large swaths being clear-cut and burned,” says Art Roffey, who owns the home with his wife, Gail Danto.

“We spent time with the tribal people, and they would talk in terms of being custodians of their land, but they were seeing it disappear,” he says. “That was a big influence for wanting to build our home.”

The couple also noticed the recession of glaciers in the Andes. So, when they decided to build their house on Indian Pond, they were keenly aware of the environment.

The 1950s-era home formerly on the site was deconstructed, and all the materials were recycled and donated to the non-profit Architectural Salvage Warehouse of Detroit.

“We wanted to build a house that was beautiful and elegant and also honor the environment at the same time,” Danto says.

By all accounts, they accomplished that, with the assistance of Bloomfield Hills-based Young & Young Architects (Don Paul Young was the principal architect); LEED consultant Jim Newman, from Newman Consulting Inc. in Bloomfield Hills; Joseph Maiorano, from the Artisans Group in Royal Oak; and interior designer Diane Hancock, of Diane Hancock Designs.

At press time, the house was under review by the U.S. Green Building Council for Platinum certification — the highest level. The design also resulted in five 2011 Detroit Home Design Awards last March.At press time, the house was under review by the U.S. Green Building Council for Platinum certification — the highest level. The design also resulted in five 2011 Detroit Home Design Awards last March.

The home, which Roffey and Danto moved into in January 2010, is green as grass: Heating and cooling is geothermal; electricity is supplemented by 30 solar panels; a graywater system filters and stores water for non-drinkable reuse; the roof is recycled copper; and all appliances are Energy Star compliant.

Sustainability harvested teak was used extensively, as was lyptus wood. “You cut it at the trunk, and it grows a new trunk, which is the ultimate in recycling,” Roffey says.

Some of the furniture was designed by Hancock, who used recycled materials for fabric. Several Hancock-designed pieces were made by local artisans, Danto says.

Wherever possible, recycled or repurposed materials were employed. A circa 1900 leaded-glass window, bought at Materials Unlimited in Ypsilanti, is in the kitchen. Several Art Deco light fixtures and grates were also repurposed.

“We like integrating old and new,” Roffey says, and that sentiment extends to their extensive art collection.

“We have a lot of old Peruvian art,” Danto explains, “but we also have a large art glass collection, which is very contemporary.”

Weavings from Bolivia, Ecuador, and Peru mingle with Asian art. Several of the artworks are displayed in lighted niches throughout the 7,500-square-foot house.

“A natural swale cuts through the middle of the property and actually bisects it,” Roger Young says. The solution was to create two sections, eastern and western pods, linked by a bridge. Echoing Frank Lloyd Wright’s organic-architecture philosophy of bringing the outdoors in, the architects created the home so that it’s flooded with natural light from copious windows and skylights.

Young also strove for an organic flow, “to create spaces that aren’t rooms. There’s a big difference.” That effect was achieved by fewer walls and doors, which delineate space.

The outdoor property was also designed with an eye toward the environment.

“The whole landscape is indigenous materials, and all the plants are drought-tolerant,” Young says. But, he adds, it was a tough sell to local officials.

“In Bloomfield Township, as in most municipalities, you have to have lawn,” he says. “So we had to convince them that these hedge grasses grow to a certain height and then stop growing. Eventually, they got on board.”

For Young, that victory was sweet, because it’s paying dividends.

“When you walk into the Bloomfield Township building department, there’s a huge LEED wall with testimonials on how others can go green,” he says. “They use this house as a case study.”

More details http://leedforhomesusa.com/drc/roffey.pdf

BY GEORGE BULANDA

http://www.detroithomemag.com/Detroit-Home/Summer-2011/Taking-the-LEED/

PHOTOGRAPHS BY JUSTIN MACONOCHIE

|

The downstairs sitting room, rife with art, contains a bar in the background. The fabric on the blue chairs is made from bamboo.

|

Like the floors, the spiral staircase is made from plantation-grown teak. The cylindrical column in the center is made from recycled steel and supplies heating and cooling. A skylight is at the top. The stained-glass window in the rear was designed by architect Don Paul Young. On the wall hangs one of the couple’s many South American weavings.

|

Lighted niches supply a home for many of Art Roffey and Gail Danto’s artworks. This glass, metal, and stone piece is by Herb Babcock, chairman of the glass department at the College for Creative Studies.

|

The hallway is drenched in natural light from the skylight.

|

A bridge connects the home’s two pods.

|

A lower-level sitting room containing a daybed can also be used as another guest bedroom. The Asian screen at right was bought several years ago by Gail Danto. The large window (all windows have low-e coating) brings nature indoors.

|

The guest bedroom contains a large wall painting by CCS grad Kyle Benning.

|

The kitchen contains a circa 1900 leaded-glass window (top) bought at Ypsilanti’s Materials Unlimited. The cabinets are made of lyptus wood. When the trunk of the tree is cut, it grows back, a process Art Roffey calls “the ultimate in recycling.”

|

A cascading beaded-glass chandelier in the dining room. Art Roffey and Gail Danto have an extensive contemporary glass collection; the bowl on the table was bought at the Ann Arbor Street Art Fair.

|

The living and dining rooms flow seamlessly, without conventional walls and doors limiting space. Natural light spills into the living room through abundant windows. The teak on the ceiling recess matches the floors.

|