Massachusetts Net Positive LEED Platinum Modern Farmhouse becomes a zero energy hero

/0 Comments/in Local, Massachusetts, Net Zero, Project Profile, Project Type, Single-Family Projects, Zero Energy Capable, Zero Hero Award/by Brett LittleGrand Teton Eco-Smart Home goes LEED Platinum & Zero Energy Capable in IL

/0 Comments/in Local, Certified Homes, Certified LEED, Illinois, Indiana, LEED Platinum, Michigan, Minnesota, New Home, Ohio, Platinum, Project Profile, Project Type, Single-Family Projects, Wisconsin, Zero Energy Capable/by Brett LittleWalsh Family Zero Energy Capable Farm House goes GreenStar Gold!

/0 Comments/in Certified Homes, Green Home Institute, GreenStar, GS Gold, Zero Energy Capable, Zero Hero Award/by Brett LittlePassive House in the Woods – GreenStar Gold

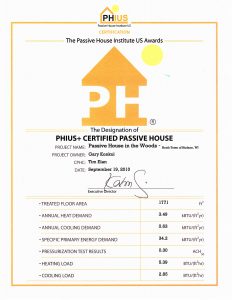

/0 Comments/in Local, GreenStar, GS Gold, New Home, Passive House, Wisconsin, Wisonsin, Zero Energy Capable, Zero Hero Award/by Brett LittleThe Passive House in the Woods [Konkol residence] is a single-family home located in the Town of Hudson, Wisconsin. Located on a one-acre lot on the outer edge of a residential development the home overlooks the St. Croix River valley. The building lot provides stunning views and prime passive solar exposure. With its renewable energy systems, the structure makes more energy than it consumes. It features three bedrooms and three levels, including a walkout basement, as well as a rooftop terrace.

The insulated concrete form substructure was built in the winter of 2009/10, and the home finished in September of 2010. The project is Wisconsin’s first certified Passive House and at the time, one of only a handful of certified Passive House projects in the United States of America.

The building envelope of the Konkol residence is very uniform. The below and above grade walls are made from the same insulated concrete form (ICF) assembly with exterior insulation and finish system. The basement slab rests on foam insulation—the roof deck is topped with foam insulation. The continuous concrete pour inside the ICF forms offers tremendous strength and helps with airtightness. R-values are very high and continuous. Both the garage as well as the exterior steel stair and deck structure are self-supporting and do not interrupt the building envelope.

The North side of the home is largely covered by the garage, which is essentially built up to the home but does not share any assemblies with it—making the house’s envelope continuously the same. There aren’t any windows on the North side at all. The south side opens up for maximum solar heat gains, which are managed by motorized exterior shades.

Covered entry and garage access are located on the main level from the East. The main stair is located along the North wall with storage cabinets lining it on each floor. The main level holds the kitchen, dining, and living area, as well as a powder room. Storage, mechanicals, and a guest suite/ family room are located on the walkout level, which provides access to the backyard.

The upper floor contains two bedrooms and a joint bath/ laundry room. Both the main and upper floor offer access to the exterior decks on the West side, as well as the exterior stair structure on the North side, which connects all levels from the ground to the rooftop terrace. The rooftop terrace holds part of the photovoltaic system and the solar thermal panel. It offers spectacular views over the St. Croix River valley.

The building was designed from the outset to become a Passive House. The first energy model was completed during schematics and subsequently kept current with design evolutions. The construction methods were selected specifically with airtightness in mind. Fenestration and glazing were fine-tuned using the energy model.

In an effort to deliver a holistic and sustainable design, the building was also designed to meet the Minnesota GreenStar Gold level of certification focusing on energy efficiency, resource efficiency, water conservation, indoor environmental quality, and site and community impact.

Fast forward to 2015

This project is our first ever Zero Energy Capable Designated home which means it was designed and tested to be a low energy usage home and be completely offset by renewable energy. Not only that but the Konkol family has gone to great lengths to actually prove the home can obtain Zero Energy in their utility bills and have produced 300 more KWH than they used. This is why we are awarding them with our Zero Energy Hero award for the year 2010 – 2015. They produced 300 kwh more than they had used. You can see their energy use and generation here.

Tim Eian, the project architect explains this in more detail.

“In year 1 we identified a couple of commissioning errors, which upon evaluation, were fixed. This lead to lesser consumption in subsequent years. In 2014 we understand that the solar thermal preheater panel failed (after repeated issues with the solar thermal hardware) and it took some time for it to be replaced, during which electric resistance hot water generation caused a higher than normal energy consumption. In addition, the tracker mechanism on the PV array failed repeatedly and is, as far as I know, defunct now, leaving the panels at a static position, rather than tracking. It is very frustrating to see the renewable systems causing many problems but re-assuring for the envelope-first approach we chose.

You will note at the bottom, that despite the issues with equipment, the overall balance for the site as of last month is still net positive. Please also note that the site is on a well with water filtration, which accounts for approximately 700 kWh per year (we monitored this for a few years), which a home on the water grid would not incur. The owner also maintains a large edible garden, which needs watering in summer and fall. The meter is accounting for all site loads, including the water well and filtration system, exterior lights, etc.”

You can read more about the project costs from this recent Fine Home Building Article

http://www.finehomebuilding.com/item/143324/the-low-cost-of-passivhaus-living#ixzz3pmBZl3PB

Highlights

• Passive House solar design

• Certified Passive House, PHIUS+ and GreenStar Gold

• 4.7kw Photovoltaic and solar thermal renewable energy systems

• Modern custom design, compact floorplan layout

• Very high-performance thermal envelope R-70 walls, an R-60 slab and an R-95 roof.

• Rooftop terrace and green roof

• Interior walls are made with American Clay Plaster which healthier material that manages moisture

• Extensive gardening

• German-made Optiwin windows and motorized exterior sunshades

• Heat-recovery ventilation system with earth loop

preheater

Project Team

Design: Dipl.-Ing. Tim Delhey Eian, TE Studio, Ltd.

Interior Design: Christine Frisk, InUnison, Inc.

Landscape Design and Civil Engineering: Laurie McRostie

Structural Engineering: Mattson MacDonald Young

Lighting Design: Carol Chaffee, Carol Chaffee Associates

Construction: Morr Construction

Renewable Systems: Energy Concepts

GreenStar Rater: Pat O’Malley – Building Knowledge

Wisconsin Passive House owner says drop on by anytime!

/0 Comments/in Local, Common Myths, LEED Platinum, Net Zero, Passive House, Single-Family Projects, Wisconsin, Zero Energy Capable/by Brett Little“I want as many people to come into this house as possible. Anyone who reads this can knock on my door and I’ll give them a tour. The whole point is to share and learn from each other, to take ideas from here and do them elsewhere.” – Sonya Newenhouse

With Carly Coulson as the certified Passive House designer. This tiny (968-square-foot) kit house has a treated floor area of  888 square feet (82.5 m²). This project sports local windows and Cardinal triple-pane glass, while the doors are Energate. The NewenHouse is wrapped in a jacket of cellulose – and similarly comes in well under the specific space heating demand.

888 square feet (82.5 m²). This project sports local windows and Cardinal triple-pane glass, while the doors are Energate. The NewenHouse is wrapped in a jacket of cellulose – and similarly comes in well under the specific space heating demand.

Carly recently presented the project at the Hannover Passivhaus conference. Here are some of the project specs:

- Space heating demand: 11.4 kWh/m²a (3.61 kBTU/ft²a)

- Primary energy demand: 104 kWh/m²a (32.9 kBTU/ft²a)

- Blower door: 0.51 ach50

- Wall U-factor: 0.09 W/m²K (R-63)

- Slab U-factor: 0.10 W/m²K (R-57)

- Roof U-factor: 0.06 W/m²K (R-94)

- (7,795 HDDs)

The project is also rocking a solar domestic hot water system (Velux) that is expected to provide nearly two-thirds of the domestic hot water needs, and a PV system for site net zero energy.

The project went through BRE in Watford, UK, for Passivhaus certification, is Energy Starcertified, and is expected to hit LEED for Homes Platinum after Landscape verification by the Green Rater Laura Paprocki.

Total cost for NewenHouse – including solar DHW, PV, and accessory structures – is a whopping $173/sf. If there was a LEED Titanium, this über-tiny Passivhaus in an “extreme” environment would surely qualify.

Newenhouse, who aptly describes herself as an eco-entrepreneur, is also founder and president of Community Car LLC in Madison, and just sold the Madison Environmental Group, a business she founded 13 years ago, to an employee. In the next year, she plans to launch a business selling three house designs — a 500-square-foot one-bedroom, an 800-square-foot two-bedroom, and a 1,000-square-foot three-bedroom. An option for a detached stuga, Swedish for “cabin,” includes storage space, a root cellar, sleeping loft, sitting area and wood stove. With her business, Newenhouse says she is trying to bring together three movements: the green building movement, the small house movement and the sustainable- or simple-living movement.

A brief overview of her kit house can be found at http://www.madisonenvironmental.com/documents/NewenHouseHandout_10%2010%2011%20(3).pdf

You can contact Newenhouse at 608-220-8029 or Sonya@madisonenvironmental.com. A link to her blog is on the a at madisonenvironmental.com. Or if you’re planning to drop in, which she says she welcomes, she lives at 422 Hickory St. in Viroqua WI.

Want to learn more about Passive House features & LEED? is hosting a free webinar of another Homeowner’s journey in Michigan who attempted passive house & is on track for LEED Platinum. Missed it? It will be recorded and a 2 hour video series on it’s construction & post occupancy living will be out by Fall. https://greenhomeinstitute.org/education-and-events/a-journey-to-passive-house-leed-homeowners-tale-free-webinar/

This article is a mash up between Joe Orso of the Lacrosse Tribune and Mike Eliason of Green Building Advisor. Their stories can be found here

Illinois Net-Zero-Energy masterpiece producing 40 percent more energy than it consumes

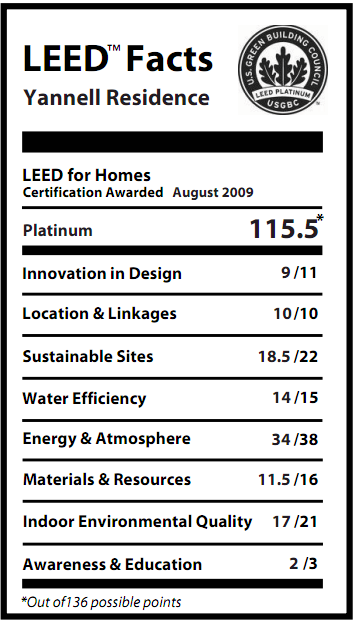

/8 Comments/in Illinois, LEED Platinum, Net Zero, Single-Family Projects, Zero Energy Capable/by Brett LittleStarting with an eco-conscious dream for a truly green home transformed owner Michael Yannell’s Chicago residence into a $1.6 million, two-story 2,675-square-foot, four bedroom and two-bath Net-Zero-Energy masterpiece, producing 40 percent more energy than it consumes.

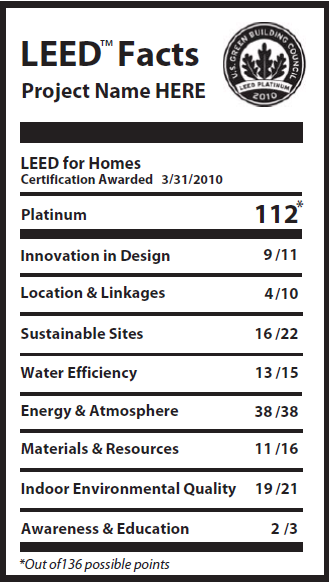

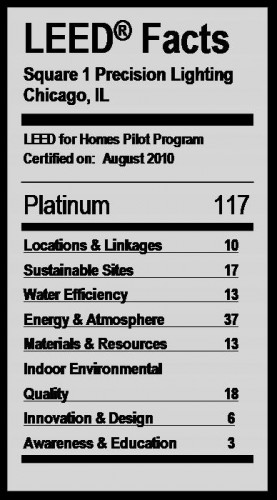

Completed in 2009, it is not only Chicago’s first LEED Platinum-certified home, but it has scored higher than any other LEED-certified project in history. Architect Farr Associates, builder Goldberg General Contracting Inc. and engineering MEP firm dbHMS created this urban infill project to utilize aspects of alternative energies through passive solar, solar grid technology, a greywater system and closed looped geothermal heating and cooling components. According to owner Michael Yannell, the main goal of this project was to create a more energy- and water-efficient, environmentally conscious place to live and to set an example by building a home as sustainable as possible. Incidentally, the green materials generally were no more expensive than conventional alternatives.

This Net-Zero-Energy residence was built using the U.S. Green Building Council’s (USGBC) LEED for Homes Pilot Program regulations. In order to earn the coveted LEED Platinum-certification, a project must meet the 100-point requirement, in which the Yannell residence scored 115.5. According to Net-Zero statistics, the Yannell residence generates 18,000 kWh/yr and uses only 12, 689 kWh/yr, earning the Yannell property an approximate $52,000 in tax credits in 2008-2009.

According to Jonathon Boyer, principal and director of architecture for Farr Associates, the permit and design processes were a challenge from the beginning, but thanks to help from a hand-picked team, deadlines were met and the project was a success.

“We put together a team of engineers, contractors, and a landscape architect, and the entire project was a team effort,” Boyer said. “Building Net-Zero-Energy is very difficult, and it requires cooperation between all components and consultants. We believe we’ve broken the sound barrier with this house, especially in the Chicago area.”

This being the first LEED-certified home came with obstacles along the way. According to Boyer, by creating new systems such as the greywater system, which recycles water used from the washing machine for the toilets, it was tricky trying to solidify the permit process. It has opened up new options for Chicago to consider when building more sustainable homes.

“It was a learning process, the city of Chicago was open to it. We didn’t have any hard and clear standards in the city for permitting this kind of system,” Boyer explained. “As a result of this house, the city of Chicago Committee of Standards and Tests is adopting a new state / city code for rainwater / greywater reuse. “We were pioneers and induced the city to think about changing permits to use more sustainable elements into the residential market,” Boyer said.

Other than utilizing alternative energies, the Yannell residence’s modern design integrated into the traditional neighborhood fuses form with function in a dense infill space. The home was built on a recycled lot where the previous building could not be salvaged. Boyer explained that typically energy-efficient homes are bland and lack style, but in this case, the owner and the building team wanted something well-designed and unique.”He [owner, Michael Yannell] wanted

something aesthetically compelling and functional,” Boyer said.

The floor plan is designed as a dual-wing connected by a foyer, which acts as an entry and passageway, both equipped with south-facing windows to utilize natural light and garden views. The positioning of the wings help compete with the Midwestern climate year-round. With temperatures ranging from the high 90s in the summer to blistering zero-below winters, it was crucial to find the most sustainable design possible. Each wing has a uniquely shaped multi-functional V-shaped green-roof designed for stormwater management and for concealing the 48 photovoltaic grids on the home. “The

butterfly pattern roofs are designed to screen the solar panels from view, while providing an ideal angle for the panels to harness the sun’s energy,” Boyer said. Although the Yannell residence has received the highest LEED score, the materials it took to achieve the title are not unattainable for other eco-conscience projects. According to Boyer, “LEED for Homes is less than $3,000 for certification.” In this case, it assisted in the construction process by acting as a detailed guide when installing aspects such as air quality, water systems and when planning the positioning.

Although there is no set specific standard definition for a Net-Zero- Energy home, Boyer said that there are other homes out there that claims to be Net-Zer-Energy, but many have only lowered their energy consumption. Only the Yannell property has the data to back it up. According to Principal of MEP firm dbHMS, Sachin Anand, “It’s [the Yannell residence] the future of housing and power generation where each home is a greenhouse emission-free power plant.”

View LEED for Homes Project Profile

http://www.elledecor.com/image/tid/5950

Photography By Christopher Barrett. Evan Lancaster is an editorial assistant at Green Homebuilder magazine. He may be contacted at elancaster@penpubinc.com.

Built for the Future. The Yannell residence in Ravenswood, Ill., a traditional neighborhood outside of Chicago, breaks barriers of traditional homebuilding by perfecting green practices. From http://www.greenhomebuildermag.com/fall42.php

Saranac McClellan Home goes platinum + zero energy in West Michigan

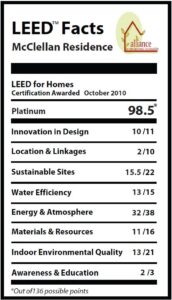

/2 Comments/in LEED Platinum, Michigan, Net Zero, Single-Family Projects, Zero Energy Capable/by Brett LittleThis 3-bedroom home with an attached 2-bedroom mother-in-law cottage provides living, workshop and home-office space for the homeowners and their mothers. It features barrier-free design throughout with zero-step entry, low thresholds, roll-in showers, grab bars, and knee-space under sinks and cooktops.

The super-insulated shell uses double-stud wall construction with 24,000 pounds of recycled cellulose insulation in the walls and attic, and a 6-inch layer of reclaimed foam insulation under the stained concrete floor. Heat from six flat-plate solar collectors is stored in an insulated 2,500-gallon water tank, which warms the floor and also provides most of the heat for domestic hot water.

High-efficiency wood stoves make up the balance of winter heating needs, and a small electric backup heater maintains temperatures when necessary. The home is designed to produce more electricity than it consumes on an annual basis.

The home has no lawn and is surrounded instead by gardens. The steel roof collects 2,000 gallons per inch of rainwater, which is stored in an 11,000 gallon cistern for garden irrigation and flushing toilets. A root cellar built into the hill behind the house provides zero-energy cold storage of fruits and vegetables.

As of October 2010 the Jay & Liz McClellan home officially earned a LEED Platinum rating, which is the highest of 4 levels of certification offered by the USGBC. They achieved a HERS index of 20, which one of the best in the state of Michigan.

This summarizes our energy production and consumption for calendar year 2011.

Statistics

Solar electricity produced: 6033 kW h (16.5 kW h per day)

Electricity consumed: 6150 kW h (16.8 kW h per day)

Non-heating: 5350 kW h, heating: 800 kW h

Net electricity deficit: 117 kW h (-2%)

Discussion

“Our first 12-month report started April 1 2010 when we first activated the PV system and went through April 1 2011, but this report covers calendar year 2011 so there are a few months of overlap. For calendar year 2011 we fell just short of our goal to produce more electricity than we consumed, with a net deficit of 117 kW h for the year. Compared to our first 12 months of operation, average daily production dropped by 0.3 kW h but consumption increased 1.8 kW h. Some of that is due to having an additional family member living here since mid-year, and some is due to adding an upright freezer that uses about 1 kW / day.”

“Below is a graph showing the inside (red) and outside (blue) temperatures that we recorded throughout the year. Overall the house was very comfortable, with just a few days in the upper 70s during some hot summer weather when allergies made us reluctant to open up the house at night since our ventilation system filters out pollen from the incoming air.”

“The graph below shows the heat storage tank temperatures over the year. The big gap is when we drained the tank due to a leak, and we were able to get the tank warmed up again in the fall but not to the degree we would have liked.”

Follow their blog at http://brainright.com/

The Isabella MN Ecologically Balanced Building goes to the Wolf Ridge Environmental Learning Center

/2 Comments/in LEED Platinum, Minnesota, Net Zero, Passive House, Single-Family Projects, Zero Energy Capable/by Brett LittleImagine that every building maintained the ecological balance needed to sustain life on earth. Then, imagine all of humanity motivated to take action, to make this dream a reality. An immensely complicated goal? Maybe. But if we put our fears of failure at the back of the bus, we will maximize the possibility of success.

View & Download Project Profile Here

An immensely complicated goal? Maybe. But if we put our fears of failure at the back of the bus, we will maximize the possibility of success.

Nature has provided us with many examples of “buildings” that achieve an ecological balance. If we follow her example, it is indeed realistic to believe we can prevail.

An Ecologically Balanced Building (EBB), then, is the most advanced building possible for our times  because it strives to replicate the ecological balance found in nature.

because it strives to replicate the ecological balance found in nature.

An EBB incorporates a multitude of interrelated, smart design choices, resulting in a building that virtually lives and breathes, is beautifully balanced, aesthetically pleasing, and is socially responsible and sustainable. It must meet the following criteria:

1. Generate more clean energy than it uses.

2. Sustainably manage the use of water.

3. Waste nothing.

4. Adapt to new conditions.

5. Work symbiotically with all other living things.

6. Eliminate toxins and pollutants.

7. Add beauty & justice to our world

We have the technology and the building science to achieve these lofty imperatives. Fortunately, we are also able to monitor, measure, and verify claims that a building actually accomplishes its intended goals. If we can’t prove our claims, they are meaningless.

The Isabella EBB Project’s initial goal was to create the most environmentally conscious building possible. It targeted integrating all seven design criteria listed above. Additionally, each criterion is monitored, measured and verified to prove, we can indeed live in balance with nature. Following is a description of how the Isabella EBB Project integrated the design criteria:

1. The Isabella EBB Project was designed to consume an annual energy load of 4.5 kBTU/sq-ft. It achieved Passive House Certification, (HERS rating of 3), as the design method to achieve this extremely low energy use index. This is similar to having a 200 MPG car in lieu of our standard a 25 MPG car. There are 9,700 Heating Degree Days in this climate zone & 189 Cooling Degree Days. This was accomplished through the design and construction of thermally broken/R 55 walls and R 90 roof, the use of high performance windows with glazing selected specifically to optimize the solar gain for each orientation and an air tightness of .5 air changes per hour. Using BTU meters on the heating distribution system, the system is to telling us if the design loads are being met.

2. Because extreme measures were taken to reduce the energy loads for this building, renewable energy generation produces more energy than is needed to operate the building. An 11,000 kWH per year PV system/8.4 kw peak load and 92 solar heat collecting vacuum tubes averaging 172,500 BTUs per day collect renewable energy. An experimental long term solar storage area using 16 inches of EPS insulation on all six sides contains both waste taconite from mines and sand. Excess solar heat collection in the summer, fall and spring are stored in this solar storage containment area under the building. The monitoriong system is gathering temperatures of the containment area, the Kwh generated and used and kBTUs for the collection system. We hope to prove that we are producing more clean energy than we use and that this solar storage system can be scaled down for use in other buildings.

3. Two additional areas used for solar storage: a 500 gallon water tank and an 80 gallon domestic hot water tank. These are also being monitor and measured to tell us how hot they are and how many days of cloudy conditions depletes the stored energy supply.

4. A small electric boiler is used for backup energy should the building need it due to depletion of solar energy. This boiler is also being monitor to tell us if it is being powered on. This has already proven to be a great diagnostic tool, as it told us that the relays and sensors were not properly sequenced because the boiler was turning on whenever the domestic hot water dropped a few degrees.

5. A Heat Recovery Ventilation System makes sure that the building and occupants are receiving the right amount of fresh air at the right temperature. An innovative ground loop heat recovery system is connected to the HRV to preheat the outside air prior to being heated by the exhaust air from the building. The success of preheating the incoming sub zero temperature fresh air with heated water from the ground near the footings of the building is being gathered by the monitoring system. We hope to discover a 10 to 15 degree preheating of temperature through this system.

6. A rain water collection system and vegetative roof assures that water continues to perform its job of replenishing the aquifers and supporting plants and animals that conversely support an ecologically balanced building.

7. Information being stored through the use of the monitoring system is allowing the building to be adapted to new conditions and future improvements. Security alarms, for example, are sent when power, pumps, temperatures or water levels are not performing as intended. Historical data gives us the ability to adjust and improve the performance due to accessibility to baseline and historical data.

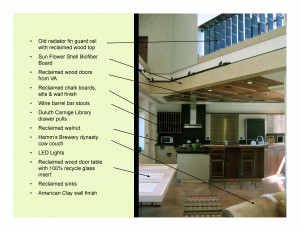

8. An extreme waste and material management system was incorporated in this EBB. Sustainable & reclaimed wood products, fast growing bio-fiber products, repurposed materials (e.g., old doors for ceilings, old radiators fins for guard rails, old wine barrels for chairs, old chalk boards for sills, and reclaimed tile), contribute to achieving zero waste and low life cycle assessment values.

9. Two highly recognized environmental third party auditing/certifications (LEED and Passive House) were achieved for this project, certifying the project at it the highest level possible. This achievement summarizes that there were many other features, to lengthy to describe for this entry, that make this project one of the most advanced ecologically balanced buildings of our times.

10. Social justice and beauty are parts of ecology that acknowledge the value of spiritually engaging people through art while also supporting the notion of providing equal access and opportunities to all people. The Isabella EBB project embraced adding beauty through the creation of a place that is welcoming, educational, inspiring, healthful, intriguing and fun. The importance of social justice was a goal that surfaced during the learning experiences of the project. Consequently, the project will be willed to the Wolf Ridge Environmental Learning Center, as an extension of their educational mission of teaching and influencing students the importance of living in balance with nature.

Isabella EBB Project Team

The critical success factors for the project team included:

1. keeping the integrated design process alive and well throughout the entire projects development,

2. checking boiler plate designs at the door,

3. if the project team achieved the goals stated above the points would follow and certification would provide the auditing needed to further validate our assumptions.

3. understanding that everyone was on a ecological educational journey

4. that fearless, open and honest communication was mandatory, (typical passive/aggressive northern climate personality styles would keep innovation from reaching its potential).

Owner: John Eckfeldt eckfe001@umn.edu

Architect/Owner: Nancy Schultz, AIA LEED AP, nschultz@compassrose-inc.com

Energy Conservation Specialist: Mikeal LeBeau, Conservation Technologies, Inc. mlebeau@conservtech.com

Builder: Brad Holmes, Rod and Sons Carpentry, mooshed2@msn.com

Electrician/Designer: Justin Bartuss, voltage@q.com

Mechanical Engineer: Bill Gausman PE, Monitoring and Verification System, bill.gausman@peopleselectric.com

HVAC & Plumbing Contractor: John Hill, Heating Plus, heatplus@frontiernet.net

Landscape Architect: Gus Blumer, SEH, gblumer@sehinc.com

Green Rater: Jimmie Sparks, The Neighborhood Energy Connection, jimmie@thenec.com

LEED Provider: Mike Holcomb, Green Home Institute, mike@homeinspectorgeneral.com

Helenowski LEED Platinum Gut Rehab showcases urban zero energy

/0 Comments/in Illinois, Net Zero, Single-Family Projects, Zero Energy Capable/by Brett LittleChicago’s Yannell residence has gained a lot of notoriety as the first “net-zero” home in the city – capable of producing as much energy as it consumes. Yet another home on Chicago’s far northwest side, the Helenowski Residence, has joined the prestigious ranks of ultra-green LEED Platinum homes. In fact, it’s one of the highest overall point totals ever achieved for a LEED-certified home.

This incredibly energy-efficient home was actually a gut-rehab of  a 1950’s brick split-level home, with a major addition, resulting in 3,300 total square feet. The owner has done an incredible amount of work focusing on the Materials and Resources as well as Energy and Atmosphere areas of the home. Some of the sample strategies include:

a 1950’s brick split-level home, with a major addition, resulting in 3,300 total square feet. The owner has done an incredible amount of work focusing on the Materials and Resources as well as Energy and Atmosphere areas of the home. Some of the sample strategies include:

- All drywall was recycled-content (for a $1 per sheet premium)

- Salvaged douglas fir from 1800’s fire-damaged building for ceiling

- Reuse or salvage for all new interior framing members

- Diversion of +90% construction debris

- Reclaimed copper for roofing and gutters

- Triple-paned Pella windows with FSC-certified lumber.

- Geothermal ground source heat pump for HVAC.

- Solar photovoltaic panels and a vertical-axis wind turbine to generate electricity.

- Motorized blinds control solar heat gain on west-facing (front) windows.

- Extremely efficient cold-cathode lighting, up to six times more efficient than LEDs.

- Roof is partially reflective white and part vegetative green roof.

Menu

GreenHome Institute

GreenHome Institute

ATTN José Reyna

1451 Lake Drive SE, #6484

Grand Rapids, MI 49516

Tel: (616) 458-6733

Email: info@greenhomeinstitute.org

About Us

Recent Posts

- April 2024 GreenHome and Sustainability Jobs Round-Up.

- Protected: Public comment on Inflation Reduction Act Home Rebates opening in MI and beyond

- Shawn Neinhouse completed Certified GreenHome Professional Training

- Please take this MSU Student’s Mass Timber Survey

- Clean Energy Credit Union Clean Energy For All Reduces Barriers